Affiliation:

1Universidad Nacional de Educación a Distancia (UNED), 28040 Madrid, Spain

2Dirección General de Salud Pública del Ministerio de Sanidad de España, 28001 Madrid, Spain

Affiliation:

3Laboratorio de Microscopía y Microtomografía Computarizada, Centro Nacional de Investigación sobre la Evolución Humana (CENIEH), 09001 Burgos, Spain

Affiliation:

1Universidad Nacional de Educación a Distancia (UNED), 28040 Madrid, Spain

ORCID: https://orcid.org/0000-0002-2812-7041

Affiliation:

1Universidad Nacional de Educación a Distancia (UNED), 28040 Madrid, Spain

ORCID: https://orcid.org/0000-0003-3503-1651

Affiliation:

1Universidad Nacional de Educación a Distancia (UNED), 28040 Madrid, Spain

Email: mdominguez@ind.uned.es

ORCID: https://orcid.org/0000-0003-1037-0542

Explor Foods Foodomics. 2024;2:43–66 DOI: https://doi.org/10.37349/eff.2024.00025

Received: October 17, 2023 Accepted: December 04, 2023 Published: February 26, 2024

Academic Editor: José Pinela, Polytechnic Institute of Bragança, Portugal

The article belongs to the special issue The food (r)evolution towards food quality/security and human nutrition

Aim: This study delves into the pasteurization process for craft beer, exploring its impact on containers and closures. Focusing on small breweries, it have been assess various treatments and find that batch immersion pasteurization post-bottling is optimal. Commercial crowns withstand pasteurization without altering the inner plastic material, crucial for extending the shelf life of craft beers, especially non-alcoholic variants.

Methods: Artisanal pasteurization of craft beer batches was performed after evaluating available methods. Given the lack of literature on craft beer pasteurization, this study offers essential insights for the artisanal beer sector. Analyses of crown corks pre- and post-pasteurization were conducted using differential scanning calorimetry (DSC) and Fourier transform infrared spectroscopy (FTIR). Organoleptic analysis of pasteurized beers was also conducted.

Results: DSC results indicate the film’s glass transition temperature (Tg) is around 62°C, while pasteurization at 66°C for 30 min did not degrade the polymer. Pressure retention and FTIR spectra show no clear differences between reference, pasteurized, and unpasteurized samples. Immersion pasteurization at 66°C with the analysed crowns is suitable for bottling craft beers without affecting polyvinyl chloride (PVC).

Conclusions: The study concludes that the chosen pasteurization process does not impact crown PVC, ensuring its suitability for craft beer bottling. Severe pasteurization can alter beer qualities, but at 66°C, no such effects were observed in the organoleptic analysis.

Pasteurization is a thermal process for preserving food, discovered by Louis Pasteur in 1864, which aims to reduce the presence of pathogenic or spoilage microorganisms in food and, thus, extend the expiration or preferential consumption periods [1]. Unlike strict sterilization, pasteurization does not destroy all the microorganisms present in the food, but rather reduces their concentration to levels suitable for consumption, altering the intrinsic characteristics of the food as little as possible: its physical structure, its chemical components and its organoleptic properties [2–4].

In the specific case of beer, its production process includes a phase that eliminates all microorganisms from the wort. This is the boiling phase after maceration and separation of the bagasse, which involves maintaining the wort boiling (approximately 100°C) for about 60 min. During this phase, the hops are added, which are also heat treated for as long as they are in the wort. All the microorganisms that can be found in beer, therefore, come from phases after boiling and before closing the bottles: cooling, fermentation or filling. Thus, there are three main routes of possible entrance of contaminants into beer after the phase of adding hops and boiling the mixture: by air, by bottles or by closures. According to Van den Bogaert [5], the most delicate point in this regard is the bottling machine since it is at this point where the greatest number of contaminations occurs. Unless it has not been done properly, after bottling there will be no new microorganisms entering the beer.

It is a fact that beer processing, as well as the alcoholic content and the hops (which have a preservative effect) provide a stable drink at room temperature and without risk for consumption, that is, with a large shelf life. However, there are a series of disturbing microorganisms that become important when the drink has a long period of delivery or when the storage conditions are not appropriate. In these cases, it is necessary to eliminate these altering microorganisms in the beer [6]. This option is especially interesting in non-alcoholic beer, since the lack of alcohol causes the beer to deteriorate earlier and its distribution period without treatment becomes unaffordable by the producers [4].

There are many microorganisms that damage food. However, in general and in the case of beer, a limited number of bacteria and wild yeasts are responsible for the spoilage. Wild microorganisms are generally defined as those bacteria and yeasts that are not deliberately used and are not under control. They include contaminating microorganisms in the inoculation and those from the air or other raw materials [7].

Undoubtedly both in the malt germination and in the subsequent phases of the beer production, contaminants can be found, but, as it has already been said, the most delicate phases are those that follow the boiling phase and the hops addition. For these last phases, according to the studies by Russell [7], the most common polluting microorganism populations in breweries are listed in Table 1.

Contaminants and caused effects

| Phase | More common contaminants | Effects |

|---|---|---|

| Fermentation | Acetic and lactic bacteria | Vinegar taste, aroma, excess carbonation |

| Bottling | Acetic and lactic bacteria, Megasphaera and Pectinatus | Strange tastes and aromas, cloudiness |

| Storage | Acetic and lactic bacteria, wild yeasts | Biofilm, cloudiness |

Large industrial breweries have different techniques to preserve the beer for longer. On one hand, they have full freedom to add authorized preservative additives included in European Commission (EC) Regulation 1333/2008 [8]. On the other hand, they have high-performance equipment that disinfects bottles or cans in situ and vacuum packages, which avoids possible contamination during the phases after the boiling of the worth. The more modest breweries, which generally include craft breweries, do not have such equipment and have to use bottling systems that are more susceptible to contamination. The craft breweries, in addition, have limited the use of preservative additives by regional regulations in the field of craft food, and all the operations that are proposed, including pasteurization, must be carried out with artisanal technologies, which is an additional challenge.

Pasteurization of beer allows the elimination of microorganisms [3, 9], but it could also affect the beer itself [10] and the packaging. In the case of bottled beers, it is understood that neither the glass nor the metallic material of the crown is affected given its high melting point (above 1,000°C in the case of glass and above 1,400°C in the case of steel, common metal of the crowns) in relation to the temperatures used in pasteurization (below 80°C). In this work it is shown that, in addition to glass and metal, well-performed craft pasteurization does not affect the qualities of the plastic material for the inner coating of the crown, an element responsible for the water tightness of the container.

Unpasteurized craft beer can be stored in unadulterated conditions for long periods of time in cool places protected from sunlight.

However, it is not the case with non-alcoholic craft beer. In fact, if there is no kind of pasteurization or additional preservation system, some food quality assurance entities impose such short distribution times for non-alcoholic craft beer (four months) that from a commercial point of view they are not operative. For this and other reasons, it is often necessary to use preservation techniques to extend the shelf life of the products.

Conventionally, preservation methods, aimed at preventing the proliferation of microorganisms are classified into two groups:

Chemical preservation. It involves changing the composition of the food beyond the extraction of the water. This group includes preservation with addition of salt or vinegar, as well as the use of preservative additives such as sulphites.

Physical preservation. It maintains the composition of the food, although it can modify its physical structure. Included here are methods that vary the temperature or the proportion of water (drying, dehydration), and those that use radiation or high pressure.

Given the nature of the food that it is wanted to preserve, maintaining its characteristics at the time of purchase by the consumer and later, it is directly discarded the chemical preservation techniques as well as the physical ones of variation of the water proportion.

Preservation by refrigeration, widely used in other fresh beverages because the low temperature delays the development of microorganisms, is an ineffective alternative for the distribution of non-alcoholic craft beer. This option, in addition to making the product enormously expensive, would imply different distribution systems for alcoholic and non-alcoholic beer.

The work is therefore focused on heat preservation: heat treatments. Depending on the temperature reached, which is related to the microorganisms it neutralizes, there are pasteurization and sterilization [11]. Pasteurization is considered a treatment in which the vegetative forms of microorganisms are eliminated, and sterilization is one that eliminates all microbial forms. By analogy with other heat-treated liquids, pasteurization would be up to about 80°C for a few minutes and sterilization at temperatures above 100°C for a few seconds.

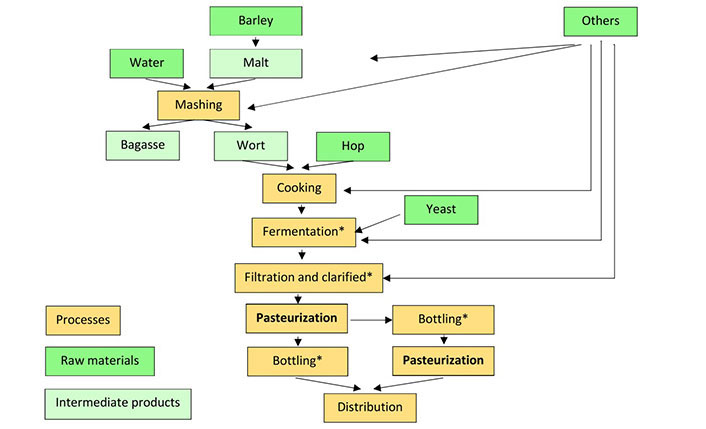

In the field of beer production, sterilization is carried out during processing, which is why it is not usual to require another sterilization on the finished product. If pasteurization is chosen, it can be applied before or after bottling, depending on the technology used (Figure 1). If it is done before, the bottling has to be done under vacuum or in inert atmospheres.

Position of the pasteurization in a beer production line. * Critical points are marked with an asterisk

Heat is lethal for microorganisms, but each species has its own tolerance-resistance. During a heat inactivation process, such as pasteurization, the destruction rate is logarithmic, as is its growth rate; therefore, bacteria subjected to heat die at a rate that is proportional to the number of organisms present. The process depends on the temperature and the treatment time. Therefore, the thermal calculations necessary for a pasteurization process require knowing the concentration of microorganisms to destroy, that is, the acceptable (admissible) concentration of microorganisms that can be left behind (non-pathogenic or in quantities so small that their growth rate makes that the food is always to be consumed before the microorganisms reach a level that can be dangerous), the thermal resistance of the microorganisms and the temperature-time relationship required for the destruction of the target organisms. The duration of the required heat treatment is determined by the heat resistance of the most heat-resistant microorganisms in the food [12].

At temperatures above 50°C, an increase in temperature of 7°C accelerates the rate of cell death by tenfold [13]. The lethal effect of the application of heat to microorganisms is a product of the lethal inactivation rate and the time of application. According to the European Brewery Convention (EBC), the lethal inactivation rate (Li) is: Li = 1.393(Tp – 60), where, Tp is the temperature in °C used for pasteurization.

In order to unify criteria and to be able to compare experiments, the pasteurization unit (PU) is arbitrarily defined as the biological destruction obtained by keeping a beer for 1 min, at 60°C (140°F) [14]. This concept was originally defined by Benjamin [5], who at the time specified it in Fahrenheit degrees (140°F). In industrial processes, beer is treated from 10 PU to 100 PU, although according to Gibbons in most cases 5 PU is sufficient [15], while Hough puts this limit at 5.6 PU [16].

When calculating the pasteurization time in bottled beer, the centre of the bottle should be taken as a reference. It is necessary to consider a time both in heating and cooling; and the insulating effect of the container should not be overlooked as well [17].

In theory, two beers subjected to the same PU have the same effect on the elimination of microorganisms, but the same does not happen with the flavours and aromas, which are more affected with higher pasteurization temperatures [18]. In fact, excess pasteurization can even be detrimental to beer [10]. On the opposing, as indicated by various authors, the flavour and aroma qualities of pasteurized beer may be better than those of unpasteurized beer [9]. Therefore, in order to correctly evaluate a beer, it is convenient to know both the number of PU that it has received during pasteurization and the maximum temperature of that pasteurization.

The mathematical formulation of the PU is directly related to the lethal inactivation rate through the time variable: PU = t × 1,393(Tp – 60), where t is the exposure time of the beer in the pasteurization process and Tp is the temperature in °C of the geometric centre of the container [19].

This means that one unit of pasteurization is the lethal inactivation rate obtained by maintaining beer for 1 min at 60°C.

The logarithmic ratio of the PU and the temperature are collected for a predetermined time equal to 1 min (Figure 2). It can be seen that at 60°C a PU is obtained, while if the temperature is raised by 7°C the number of PU is around 10, according to the criteria of Dennis and his team [13].

In order to carry out this analysis as well as possible, a series of heat preservation treatments that can be used in craft beer are listed below:

Continuous pasteurization. It consists of forcing the beer to pass through a pipe, in which the necessary temperature is reached during the established time. It is called instantaneous, lightning or flash when combinations of higher temperatures and shorter times are used. Furthermore, it is an ideal system for the industrial production of beer, but in craft breweries it has quite a few limitations. In the case of lightning, by having to reach higher temperatures, the aromas and flavours of the beer are also more affected [2, 20]. After treatment, the beer must be rapidly cooled and hermetically sealed (bottled).

Tunnel pasteurization. It consists of forcing the bottles (already closed) to pass under a shower, at a certain temperature and for a stipulated time [21]. It is an interesting technology for an industrial brewery, but perhaps not so much for a craft brewery; although if the production level of the craft brewery is high, it should not be ruled out.

Immersion batch pasteurization. This system consists of immersing a batch of beer bottles in water at the pasteurization temperature for the required time. It is a slow method, usually, if it is done by hand. If it is automated, it is probably more complex than other systems such as those described above. It is a method that is carried out after bottling, so any microorganism problems that have previously existed in the brewing process should be amended. It is a craft system, unless it is automated, and can be valid for implementation in a small brewery or a craft brewery.

An interesting topic of the pasteurization process, from an industrial point of view, is the heating and cooling of the containers during pasteurization. The mathematical models used for time calculations must take into account the thickness and materials of the container, because otherwise there will be an important difference between the pasteurization model and reality, which can make the results obtained are not the expected ones [17].

In order to provide a global vision of the subject, other conservation methods that can be used in the field of beer production are listed below:

Chemical preservation. This system is widely used in the wine sector. It can be used in beer, including non-alcoholic beer, although it can alter flavours and aromas, as well as the stability of the foam [5]. As it is a pre-bottling application system, it is appropriate to asepticize the bottling phase, although in this case the rigour is less than in other alternatives that will be seen later than chemical preservatives continue to inhibit microorganisms after bottling.

Mechanical filtration. It is a system for the mechanical elimination of pathogens using filters or membranes, which act as a filter. The pore size must be small enough to prevent the passage of microorganisms.

Most industrial beer is filtered to avoid sediments in the bottles, which can upset consumers with little knowledge of its origin. Many craft beers, and all those that carry out a second fermentation in the bottle, are unfiltered so as not eliminate the yeasts that have to carry out the fermentation that transform the sugars still present in the beer, into alcohol and CO2. In addition, filters or membranes often have cleaning problems and a high cost, which is not ideal for small producers.

Special care must be taken because there are very small microorganisms that can pass through membranes with a pore size of 0.8 μm, a dimension that yeasts, for example, do not pass through. Depending on the membrane material, adverse effects can be had on the aroma and flavour of beer [5, 22].

Pulsed electric fields. This technology is applicable to wines and beers that are treated before packaging. Although the defenders of this technology claim that it does not affect the aromas and flavours of beer [23–25], it is not an ideal technology for artisanal processes due to their cost.

Ultrasonic treatment. A procedure is still in the field of research, as there are not many works on it. It does seem that it is clearly useful to control some type of pathogen [26], but there are no data on the usefulness of this procedure with a general approach. It does not seem, at least for the moment, an ideal system for its implementation in a small craft brewery since its effectiveness is not yet known and the cost is not low enough.

Microwave treatment. This technology is applicable to a large quantity of food, both solid and liquid and, of course, to beverages. It is similar to a traditional pasteurization, but the temperature is reached by microwaves, which are themselves lethal for many microorganisms [27, 28]. It is done before bottling, so again it is not suitable for the small brewing company.

It is interesting to note that in this technology studies have been found that evaluate the effects of microwaves on plastic trays where food is transported during baking, finding technologically valid materials for this type of process [28].

High pressure treatment. This technology achieves the control of pathogens without heating the drink but raising the pressure, usually hydrostatically [29–31]. It is an interesting technology for an industrial brewery, but perhaps not so much for a craft brewery; although if the production level of the craft brewery is high, it should not be ruled out. However, this pathogen control is previous to bottling, which makes it probably not ideal for small craft breweries.

Ultraviolet (UV) radiation. It is an interesting sterilization system that uses the power of UV rays to kill microorganisms. It is a sterilization prior to bottling and requires somewhat sophisticated facilities, which again makes it unsuitable for craft breweries [32].

Microbiological control is not a conservation system, it is a control system. The proliferation of pathogens is not prevented, it is simply evaluated and guaranteed that this proliferation does not happen or, if detected, requires that an appropriate treatment be carried out to eliminate it.

It consists of taking samples at certain strategic points of the production line and carrying out periodic analyses with each of the samples taken. It is a very convenient procedure in industrial production, where a very high level of control is required, but it is a procedure that requires an analysis laboratory and qualified personnel, elements that are not easily accessible for artisan production [4].

As it has been seen so far, the ideal conservation system depends fundamentally on the volume of production and economic considerations. Many authors document that the treatments affect the aroma and flavour of beer very little, but the truth is that, to a greater or lesser extent, all methods affect its properties in one way or another [33, 18]. Nevertheless, in some cases these variations are imperceptible for the consumer, as is the case, for example, of toasted or caramelized beers [5]. It has also been documented that treatments can positively affect beer, improving colour or decreasing turbidity, for example [2].

In the works developed by Zendeboodi and his team [4], published in 2020, it is verified that pasteurization processes eliminate a large part of the microorganisms that degrade beverages, specifically in non-alcoholic beer. Zendeboodi et al. [4] explicitly indicates the need to pasteurize or sterilize non-alcoholic beer.

As a compilation of the procedures set out in the previous sections, in Table 2 the suitability of each of them is analysed in a small craft brewery.

Conservation and control processes

| Process | Before bottling | After bottling | Economic investment requirements (high, medium, low) | Suitability for a craft brewery (high, medium, low) |

|---|---|---|---|---|

| Continuous pasteurization | Yes | No | High | Low |

| Flash pasteurization | Yes | No | High | Low |

| Tunnel pasteurization | Yes | Yes | Medium | Medium |

| Immersion batch pasteurization | Yes | Yes | Low | High |

| Chemical preservatives | Yes | No | Low | Low |

| Mechanical filtration | Yes | No | High | Low |

| Pulsed electric fields | Yes | No | High | Low |

| Ultrasonic treatment | Yes | No | High | No |

| Microwave treatment | Yes | No | Medium | Low |

| High pressure treatment | Yes | No | High | Low |

| UV radiation | Yes | Yes (with doubts) | High | Low |

| Microbiological control | Yes | Yes (destructive) | High | Medium |

Without disregarding any of the exposed processes, since each one has its field of application, in view of the results of the Table 2 the system considered ideal for pasteurization in a small craft brewery is batch pasteurization by immersion.

This project originated from a consultation made by a craft beer producer, who wanted to produce non-alcoholic beer also in a craft way. Given the restrictions imposed by the food quality assurance standard of the company that carried out the dealcoholisation, he was looking for alternatives to get the product to the market in sufficiently long consumption periods that would not make its distribution impossible.

The option that was raised, due to the infrastructure of the factory, was to pasteurize the beer after bottling in the brewing tanks, of course by artisanal procedures, in accordance with the guidelines of the policy of the brewing company.

When developing the pasteurization procedures, the question was raised as to whether or not the closing crown would be affected by the temperature changes required in pasteurization. In the technical sheet of the crowns, it was indicated that this product should not be subjected to high temperatures, but it was not specified at any point what those limit temperatures were. In the literature no studies were found in this regard, neither in one way nor in the other.

According to the technical sheet for the crowns, the closure material is polyvinyl chloride (PVC) with certain additives (plasticizers, stabilizers and other authorized additives). The technical data of PVC reveal that this material in its pure state can withstand a temperature of up to 80°C without problems but, according to the bibliography [34, 35], when plasticizers are added to PVC to improve its flexibility, its glass transition temperature (Tg) can drastically decrease reaching values even lower than 50°C, a temperature that can conflict with a pasteurization process.

Put in contact with several crown manufacturers, they were consulted. Some manufacturers simply did not reply, others replied stating that they had no data. It is probably a question that the big brewers already have solved (we understand that they should have it solved), but there are no publications about it, so the small brewers have no criteria to identify how to proceed.

The option that was proposed was to pasteurize several batches, some beer without alcohol and others of beer with alcohol, all of them bottled with commercial crowns, to then analyse the materials of the crowns and study the differences before and after the pasteurization.

As mentioned, the question that arose was whether the pasteurization process could degrade the crown material in any way, due to its influence on the Tg, and whether it could cause it to be necessary to discard these commercial crowns to pasteurize craft beer after bottling.

If the material degrades, the sealing of the closure can be lost and, what is more serious, plastic microparticles associated with multiple sanitary problems can be separate. It is a problem due to their accumulation in human organs. There are several studies on problems related to the consumption of different parts of plastics, but these have so many components that all the problems they can cause have not yet been studied [36].

For the pasteurization, the immersion method was used for 30 min at a temperature of 66°C (approximately 220 PU). The objective was putting in the worst case, since pasteurization of beer does not have to be so severe. If the materials withstood those conditions, there would be no problem in processing under less severe conditions.

Several batches have been pasteurized, some beer with alcohol and others with non-alcoholic beer. In the case of beer with alcohol, pasteurization has been carried out after the second fermentation, that is, when the bottle already has the pressure corresponding to the CO2 generated in that second fermentation.

The objective was to carry out artisan pasteurization, far from the in-line pasteurization typical of industrial brewing plants.

To assess the transformations during pasteurization, various analyses of the crown cork were proposed: some pasteurized and conformed by bottling, others not pasteurized but conformed by bottling, and a third group of crowns that had not been nor pasteurized nor conformed, which constituted the reference group. The programmed analyses were differential scanning calorimetry (DSC) and Fourier transform infrared spectroscopy (FTIR).

It would probably have been ideal to carry out the analysis on the same crown before and after pasteurization, but this option is not viable since the tests are destructive.

As indicated, in all the crowns the plastic compound inside is basically made up of PVC to which plasticizers, stabilizers and other authorized additives have been added for the production of polymeric material intended to be in contact with food.

Both 26 mm crowns, the most common, and 29 mm crowns were analysed, since both options are likely to be used in the production of craft beer and can be easily obtained in the market. The results obtained are similar in both cases, so in this article only the results of 29 mm crowns are listed.

The pasteurization processes were carried out in the facilities provided by the Asociación Veterinaria para la Salud y la Calidad Alimentaria (AVeSCA, Veterinary Association for Health and Food Quality), while the analytical tests were carried out at the facilities of the Centro Nacional de Investigación sobre la Evolución Humana (CENIEH, National Center for Research on Human Evolution). The samples were initially analysed by FTIR using the Thermo Fisher Nicolet 6700 equipment. Both the external face and the internal face of the polymeric film were analysed. By external face is understood that which is in contact with the liquid, and by internal face is understood that which is in contact with the crown (the metal). Likewise, samples from the outermost part of the circle and samples from the central part (from now on edge 1, edge 2 and centre, respectively) were taken and analysed.

The same samples that had been analysed by FTIR were then used in the DSC tests. The equipment used for this study was a simultaneous thermal analyser [DSC)/thermogravimetric analysis (TGA), Netzsch, model STA 449 F5].

For this analysis, the samples were cut into small pieces (around 14 mg). Each polymeric film was analysed twice for greater repeatability using the following test parameters: heating ramp of 10°C/min, N2 atmosphere and temperature range from room temperature (20°C) to 650°C.

The coding corresponding to each of the groups of samples whose results are reflected in this article are included in Table 3. Obviously, the number of samples analysed is much higher, but in all cases the results have been similar.

Relationship between the nomenclature of the sample, the treatment and its diameter

| Sample | Treatment | Diameter (mm) |

|---|---|---|

| 3a | Not pasteurized | 29 |

| 4a | Pasteurized | 29 |

| 6a | Reference | 29 |

As it cannot be otherwise, the beer samples used in this study were subjected to a final organoleptic analysis to verify the possible variations, caused by pasteurization, in the characteristics of the beer in terms of colour, cloudiness, aroma, CO2, colour and quality of the foam, mouth feeling (tongue impression), and flavours.

Although the samples were first analysed by FTIR and then by DSC (these were performed last due to the destructive nature of this type of test), the results will be shown in reverse to facilitate understanding.

The samples were analysed by DSC in order to know the Tg of the polymer. According to the manufacturer, the film is made of PVC, so the test parameters were adapted to this material [37–39].

The curves obtained for samples 3a, 4a and 6a are shown on Figure 3, 4 and 5. Two tests per sample were carried out to have a higher reproducibility. The Tg values for each of the samples are summarized in Table 4. In the last column, the average Tg of the material has been calculated together with its standard deviation.

Tg of the analysed PVC samples together with the average value and its standard deviation

| Sample | Tg (°C) sample 1 | Tg (°C) sample 2 | Tg (°C) average |

| 3a | 65.02 | 67.02 | 66.02 ± 1.41 |

| 4a | 61.84 | 61.92 | 61.88 ± 0.06 |

| 6a | 59.89 | 64.59 | 62.24 ± 3.32 |

According to the observed results, the Tg of the material before pasteurization is around 62°C, remaining around this value in both pasteurized and unpasteurized samples. These results show, on the one hand, that since the initial Tg of the reference material is around 62°C, the pasteurization process carried out around these temperatures should not affect the properties of the material since it is being carried out at a temperature similar to the Tg of the material. At temperatures close to Tg, a softening of the polymeric material takes place, but there is no type of degradation in it (the decomposition temperature of PVC is higher than 500°C [40]). On the other hand, the values obtained show that neither the bottling process nor the pasteurization process itself affects the Tg of the materials since said temperature remains constant around 62 °C in both cases.

The Tg values obtained coincide with the data found in the bibliography [34, 35], in which it is observed that the Tg of PVC is decreased when have been added plasticizers to the pure material to improve the flexibility.

DSC results confirm that bottling and pasteurization processes do not have any clear effect on polymer properties.

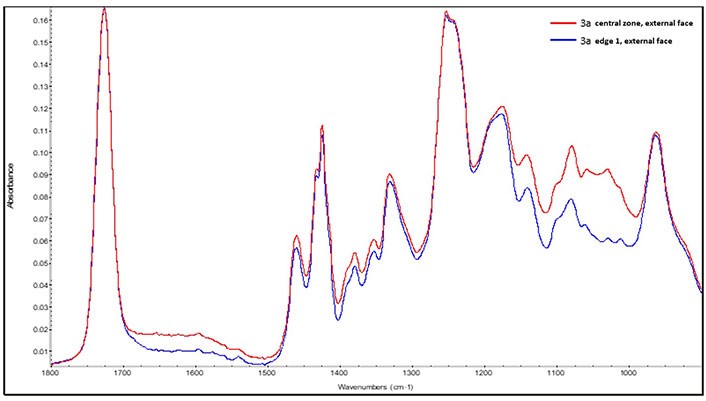

Below are the results of the analyses performed on the samples by FTIR. These analyses have the objective of detecting possible differences in the absorption peaks that could elucidate possible changes in the polymeric chains and, therefore, between pasteurized materials, unpasteurized materials and reference samples [41]. As already mentioned above, both the external and internal faces of the polymeric film have been analysed, understanding the external face as that which is in contact with the liquid and the internal face as that which is in contact with the crown.

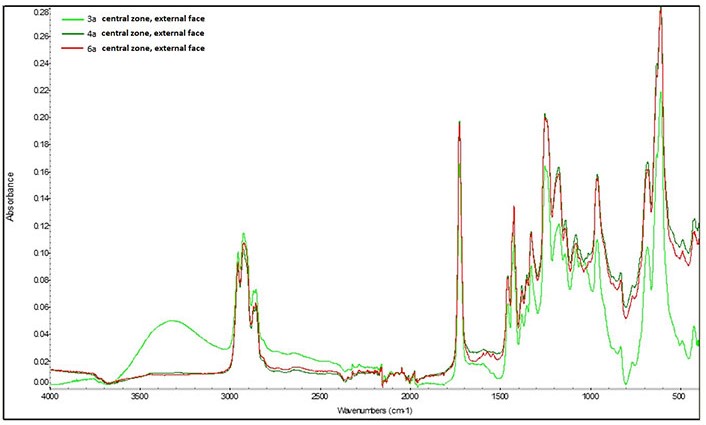

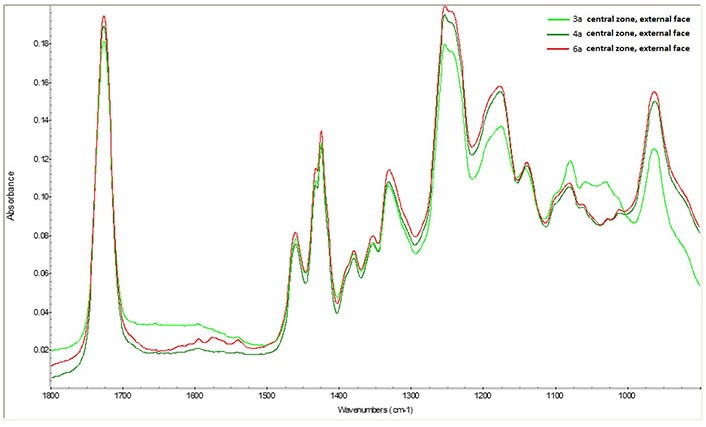

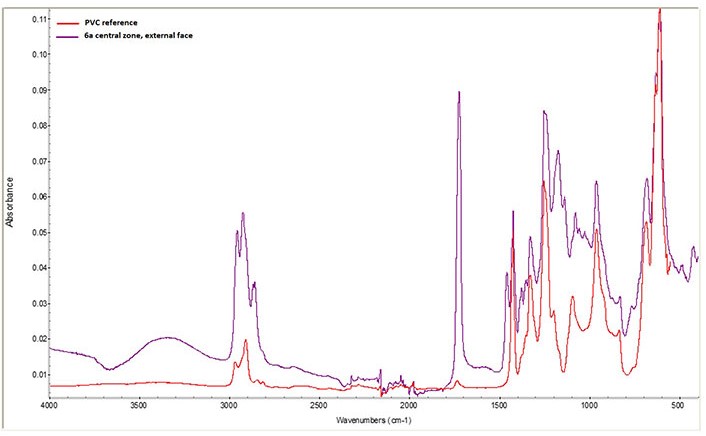

In order to analyse in detail the existence or not of variations in the infrared spectrum of the plastic compound that makes up the 29 mm crown, several comparisons of the spectra have been made (Figure 6 to 25).

The FTIR corresponding to sample 3a, 4a and 6a of the external face of the central zone of the plastic part is shown in Figure 6. The spectra of the three samples are very similar, except for very small differences observed in the peaks of the ranges between 1,700–1,500 cm–1 and 1,125–975 cm–1 (see detail in Figure 7).

FTIR spectrum of the external face of the central area of the samples 3a, 4a and 6a

Detail of the FTIR spectrum (range 1,800–900 cm–1) of the external face of the central area of the samples 3a, 4a and 6a

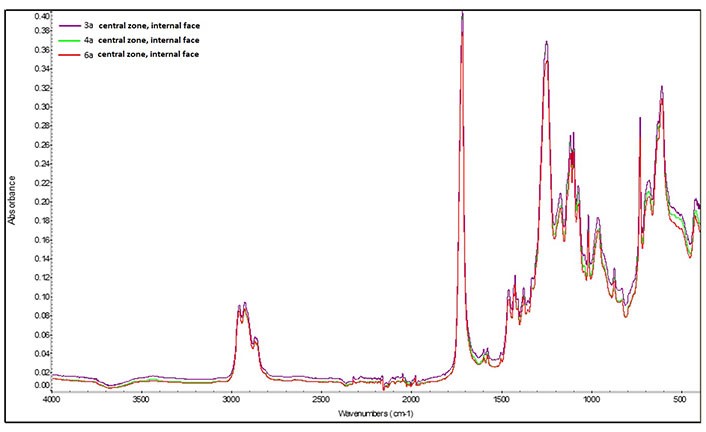

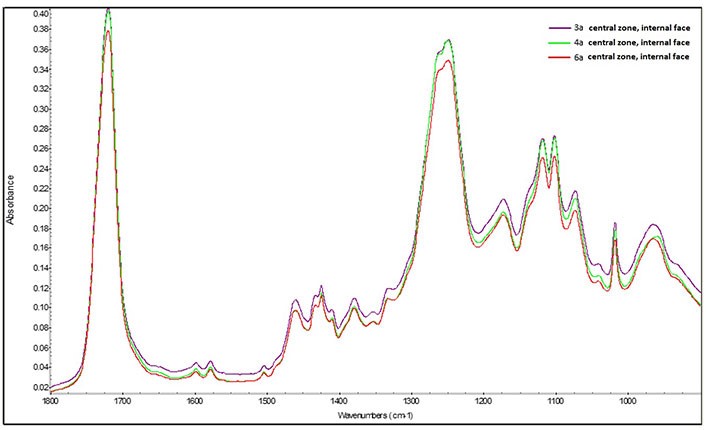

The spectra of the inner face of the central zone of the three samples are identical (Figure 8 and 9).

FTIR spectrum of the internal face of the central area of the samples 3a, 4a and 6a

Detail of the FTIR spectrum (range 1,800–900 cm–1) of the internal face of the central area of the samples 3a, 4a and 6a

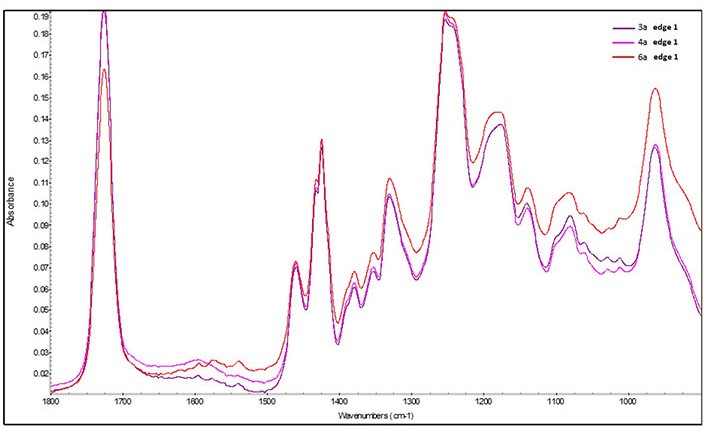

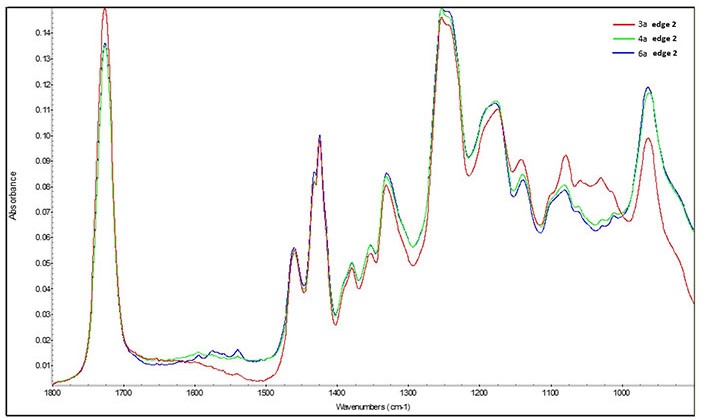

Both edge 1 and edge 2 were exclusively analysed on their external face. As can be seen in Figure 10, 11, 12 and 13, the response of the three samples is identical in edge 1, but not in the case of edge 2 where very small differences are also detected between the reference sample and the pasteurized and unpasteurized in the range of 1,700–1,500 cm–1 and 1,125–975 cm−1.

Detail of the FTIR spectrum (range 1,800–900 cm–1) of the edge 1 of the samples 3a, 4a and 6a

Detail of the FTIR spectrum (range 1,800–900 cm–1) of the edge 2 of the samples 3a, 4a and 6a

Although there are small differences in the response observed between edge 1 and 2, these are minimum, so from now, to simplify the study, only edge 1 will be used for the different comparisons made between spectra.

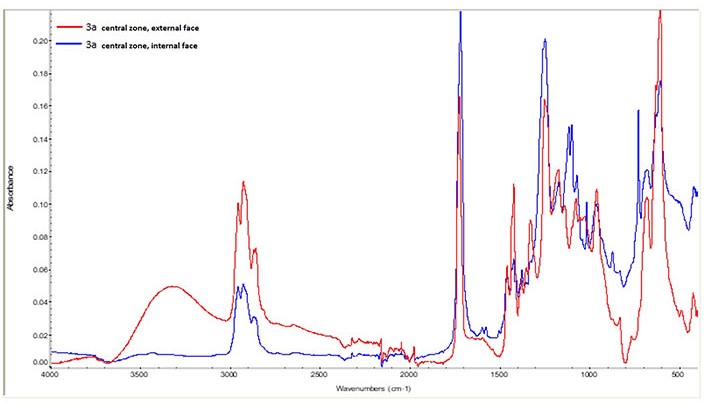

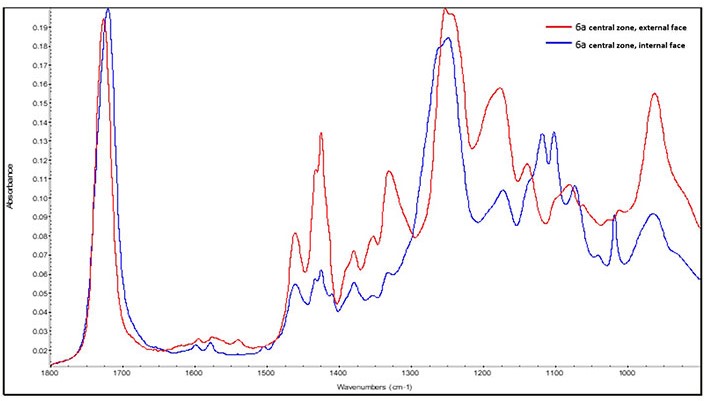

In this case, it is intended to see if there are differences between the spectra of the external and internal face of the central zone of the polymeric compound. The analyses (Figure 14, 15, 16, 17, 18 and 19) reveal that all the samples: both the unpasteurized (3a), the pasteurized (4a) and the reference (6a) respond differently depending on whether the study is carried out on one side or other. This result was expected since the internal face of the plastic compound is attached to the crown by means of some type of adhesive, so the response had to be different (appearance of new peaks corresponding to the adhesive).

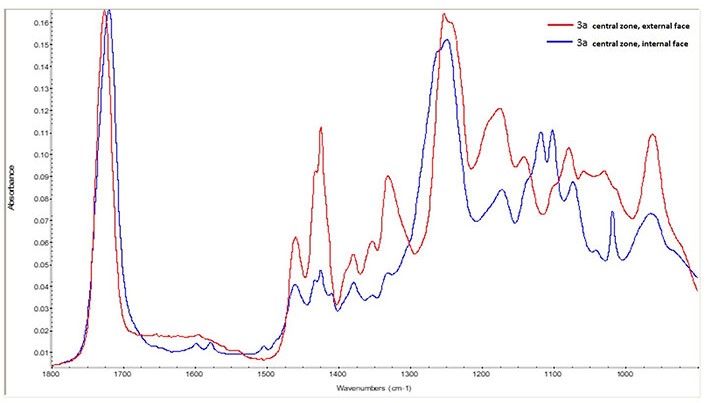

FTIR spectrum of the external face vs. internal face of the central area of the sample 3a

Detail of the FTIR spectrum (range 1,800–900 cm–1) of the external face vs. internal face of the central area of the sample 3a

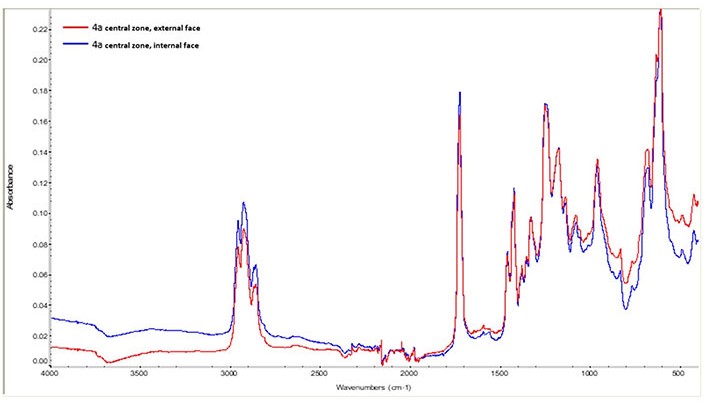

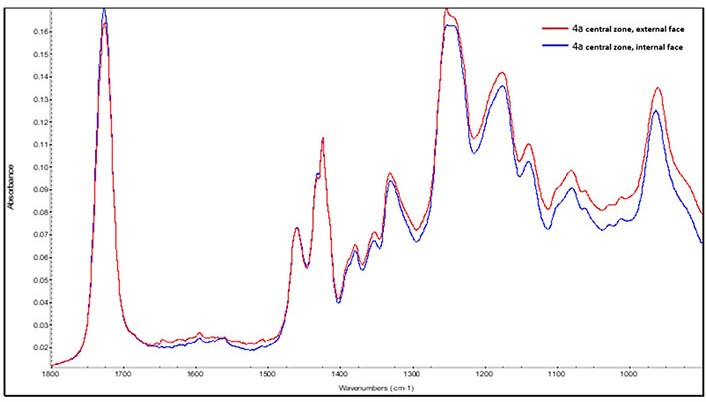

FTIR spectrum of the external face vs. internal face of the central area of the sample 4a

Detail of the FTIR spectrum (range 1,800–900 cm–1) of the external face vs. internal face of the central area of the sample 4a

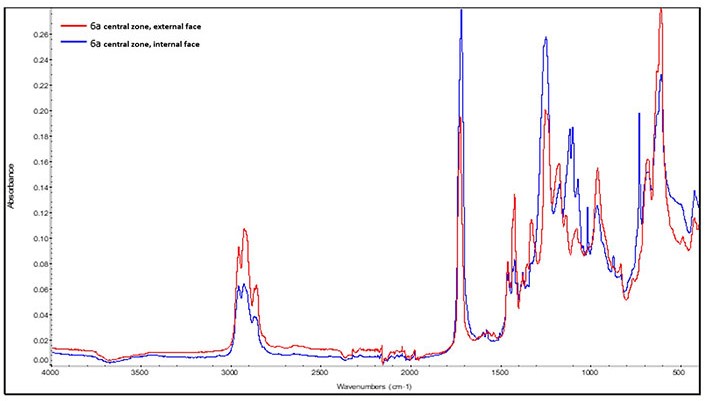

FTIR spectrum of the external face vs. internal face of the central area of the sample 6a

Detail of the FTIR spectrum (range 1,800–900 cm–1) of the external face vs. internal face of the central area of the sample 6a

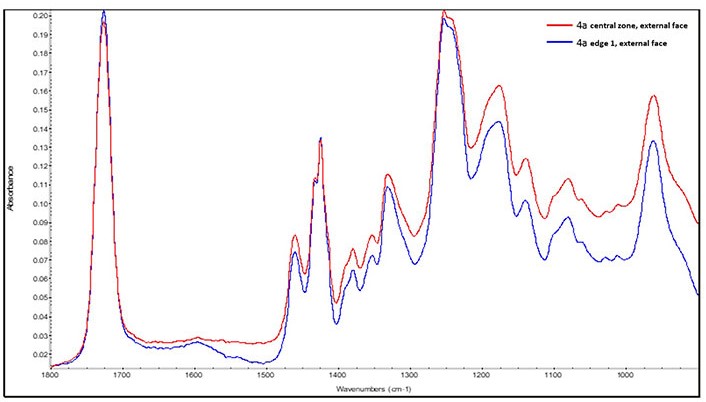

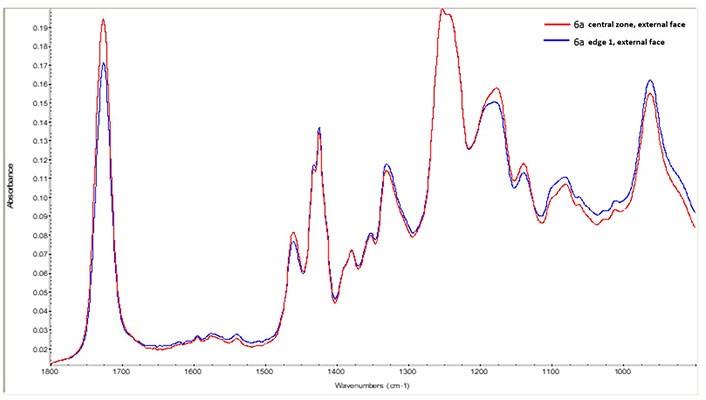

According to Figure 20, 21, 22, 23, 24 and 25, the response of all the samples in the external zone of the plastic compound, both in the central zone and on the edge, is identical, so it could be said that the polymeric film is quite homogeneous as a whole.

Detail of the FTIR spectrum (range 1,800–900 cm–1) of the external face of the central zone vs. edge 1 of sample 3a

Detail of the FTIR spectrum (range 1,800–900 cm–1) of the external face of the central zone vs. edge 1 of the sample 4a

Detail of the FTIR spectrum (range 1,800–900 cm–1) of the external face of the central zone vs. edge 1 of the sample 6a

Samples 3a, 4a and 6a have a similar behaviour on their external face in the central area except for the wavelength values between 1,700–1,500 cm–1 and 1,125–975 cm–1 where small differences are observed. Likewise, they are quite homogeneous over their entire surface, since the spectra between the edge and the centre are identical. On the other side, the internal face of the plastic compounds of each one of the samples remains unchanged, although this face does present differences with respect to the spectrum of the external face. This difference may be due to the presence of an adhesive for pasting the plastic compound to the crown.

The small differences that have been found in certain ranges of wavelengths (1,700–1,500 cm–1 and 1,125–975 cm–1) do not correspond to possible alterations of the PVC. The fundamental PVC peaks are not altered for this the spectrum of the reference sample (sample 6a) is compared with a PVC reference spectrum from the equipment database (Figure 26) but rather the differences found appear in other different regions [42]. These regions can correspond to the vibrational response of some plasticizers, stabilizers or additives that the polymeric compound contains. In view of the results of the analyses, and although the composition of these additives is not exactly known, it can be stated that their chemical composition is not affected by pasteurization, since there are no clear spectral differences between the samples before and after pasteurization. On the other side, the manufacturer ensures that these compounds are suitable for consumption, so it is to be assumed that these small variations are not a problem.

FTIR spectrum of the external face of the central area of sample 6a compared to the ir spectrum of a pure PVC reference

It is important to note that there are no clear spectral differences between the pasteurized samples and the others, since sometimes the response of the pasteurized sample resembles the unpasteurized one and other times it resembles the reference, but no case has been found that the pasteurized sample has a clearly different response than the others.

Finally, in most of the spectra, differences in intensity are observed. The FTIR technique is not the most appropriate for making a quantitative estimation, so these differences in intensity cannot be associated with any phenomenon [43]. Likewise, it has been seen that the applied pressure or the thickness of the sample influence the intensity of the spectrum [44].

As indicated, the beer samples used in this study were subjected to a final analysis to verify the possible variations, caused by pasteurization, in the characteristics of the beer. The following parameters were compared in a blind study: colour, turbidity, aroma, CO2 quantity, colour and quality of the foam, feeling in the mouth (perception on the tongue), and flavours.

For the organoleptic analysis experts and collaborators from the AVeSCA have been involved.

The results of the organoleptic analysis, although inconclusive due to the low participation, indicated little differences between pasteurized and unpasteurized beers, preventing a clear differentiation of one from the other.

In the first part of this work, it has been seen that the ideal option for beer conservation in a small craft brewery is batch pasteurization by immersion. However, if the economic possibilities of the company allow it, other alternatives can be considered.

Given that one of the unknowns raised in this work was the behaviour of the inner material of the crown with the pasteurization process, we proceeded to compare pasteurized and conformed crowns, unpasteurized and conformed crowns and reference crowns (not pasteurized and not conformed).

The DSC results reveal that the Tg of the film used in the crowns is around 62°C. The pasteurization carried out, at 66°C for 30 min, has been severe. However, the tests reveal that the material has not suffered any kind of degradation. It has been shown that the temperature chosen in this pasteurization process is not affecting the degradation of the polymer, since at 66°C only a small softening of the film occurs, without producing a degradation of the film that covers the crown. Pasteurized beers have not lost pressure, which means that softening at 66°C has not affected the tightness either. Likewise, in the FTIR spectra there are practically no differences between the reference samples, the pasteurized ones and the unpasteurized ones.

With all this, it can be concluded that the immersion pasteurization process carried out with the crowns under analysis, at a temperature of 66°C, does not affect the PVC of the crowns and, therefore, is suitable in the bottling of craft beers.

As indicated, a very severe pasteurization can alter the qualities and flavour of the beer, but this has not happened in this case either, since in the organoleptic analysis that has been carried out, it has not been possible to clear differentiate pasteurized beer from non-pasteurized beer. However, it may be not pasteurizing this product above 62°C, a more than acceptable temperature for pasteurization, and not exceeding 10 PU (the time corresponding to 10 PU at 62°C is 5.2 min)

The samples were pasteurized after bottling and after the second fermentation. Undoubtedly, this second fermentation affects the internal pressure of the bottle, due to the increase in CO2. This second fermentation is interesting in many craft beers to achieve flavours and aromas that are only obtained with the beer resting for a while. In view of the results of this study, the qualities of the plastic material inside the crown have not been altered either, despite having carried out pasteurization in a bottle with the gas pressure caused by this second fermentation.

It should be noted that the results of the analyses carried out cannot be extrapolated to other crowns that are not made of the same materials, so before choosing this preservation method it is advisable to consult the technical data sheet of the crowns. However, when in doubt, it is possible to carry out analyses such as those collected in this work.

DSC: differential scanning calorimetry

FTIR: Fourier transform infrared spectroscopy

PU: pasteurization unit

PVC: polyvinyl chloride

Tg: glass transition temperature

UV: ultraviolet

To Cervezas Mica, for the non-alcoholic beers for the development of these analyses. To the Centro Nacional de Investigación sobre la Evolución Humana–CENIEH (National Center for Research on Human Evolution) for conducting the tests in the Archeometry and Microscopy laboratories with the collaboration of its technicians. To the AVeSCA for the realization of the pasteurization processes and the organoleptic analysis.

RD and MJ: Conceptualization, Investigation. BN and LR: Investigation, Analysis. MME and MD: Investigation, Validation, Writing—review & editing, Supervision. All authors write, read and approved the final version of the manuscript.

The authors declare that they have no conflicts of interest.

Not applicable.

Not applicable.

Not applicable.

The datasets for this manuscript can be obtained by contacting the author (Manuel Domínguez, mdominguez@ind.uned.es).

Not applicable.

© The Author(s) 2024.

Copyright: © The Author(s) 2024. This is an Open Access article licensed under a Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, sharing, adaptation, distribution and reproduction in any medium or format, for any purpose, even commercially, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

Leonel Pereira

Micaela Antón ... Rafael Borneo

Eliseo Sánchez-Loredo ... Juan A. Ascacio-Valdés

Ayla Elmi Kashtiban ... Sayna Zahedinia

Shafa’atu Giwa Ibrahim, Roselina Karim

Brice Ulrich Foudjo Saha ... Lifoter Kenneth Navti

Olamide Akande ... Daniel Ajewole

Evans Ntim Amedor ... James Owusu-Kwarteng

Luís M.G. Castro ... Manuela Pintado

José Pinela, José Ignacio Alonso-Esteban