Affiliation:

1Department of Horticulture and Crop Production, School of Agriculture and Technology, University of Energy and Natural Resources, Sunyani P.O. Box 214, Ghana

Affiliation:

2Council for Scientific and Industrial Research (CSIR)-Oil Palm Research Institute (OPRI), Kade P.O. Box KD 74, Ghana

ORCID: https://orcid.org/0000-0002-3463-6694

Affiliation:

1Department of Horticulture and Crop Production, School of Agriculture and Technology, University of Energy and Natural Resources, Sunyani P.O. Box 214, Ghana

ORCID: https://orcid.org/0000-0001-8299-5889

Affiliation:

3Department of Food Science and Technology, School of Agriculture and Technology, University of Energy and Natural Resources, Sunyani P.O. Box 214, Ghana

Email: nanafrimpong94@yahoo.com

ORCID: https://orcid.org/0000-0001-5466-4425

Affiliation:

3Department of Food Science and Technology, School of Agriculture and Technology, University of Energy and Natural Resources, Sunyani P.O. Box 214, Ghana

Email: james.owusu-kwarteng@uenr.edu.gh

ORCID: https://orcid.org/0000-0002-2703-3393

Explor Foods Foodomics. 2025;3:101095 DOI: https://doi.org/10.37349/eff.2025.101095

Received: May 17, 2025 Accepted: July 23, 2025 Published: August 12, 2025

Academic Editor: José Pinela, National Institute of Agrarian and Veterinary Research, Portugal; Polytechnic Institute of Bragança, Portugal

The article belongs to the special issue The food (r)evolution towards food quality/security and human nutrition

Aim: This study examined the combined effects of pretreatment methods (blanching, citric acid, and ascorbic acid) and oven drying on the chemical composition and sensory quality of fried yam (Dioscorea rotundata) chips, aimed at optimizing processing conditions for improved product quality.

Methods: Fresh yam slices were subjected to three pretreatment conditions: blanching (4 min at 100°C), a 5% citric acid solution, and a 1% ascorbic acid solution, compared to the untreated samples (control). All samples underwent convective drying at 80°C with an air velocity of 2.0 m/s. The proximate composition and mineral content of the dried samples were evaluated using official methods of food analysis and atomic absorption spectroscopy, respectively, while the color parameters and sensory evaluations of the fried yam chips were conducted using a colorimeter and a nine-point hedonic scale.

Results: Both pretreatment and drying significantly (p < 0.05) influenced mineral content in the dried yam chips. In comparison to the control, all proximate constituents decreased after drying, except for carbohydrates, which increased in the dried pre-treated samples. The fried samples of yam chips that had been blanched for 4 min received higher acceptability scores for taste, color, crispiness, and overall acceptability on the sensory scale, compared to samples pre-treated with 1% ascorbic acid and 5% citric acid. However, the acid pre-treated samples demonstrated the least browning effect in the fried products.

Conclusions: The processes of pretreatment and drying significantly modified both the mineral and proximate composition of the yam chips, increasing carbohydrates while other components decreased post-processing. Blanched samples exhibited superior sensory acceptability across all attributes, while the acid pretreatments effectively reduced browning in the final fried products.

Yam (Dioscorea spp.) is a tuber crop that is commonly cultivated throughout the world’s tropical regions [1]. It is a staple food crop in West Africa, second to cassava and maize, and consumed on a daily basis by approximately > 300 million people [2]. Nigeria is the largest producer of yams worldwide, followed by Ghana, Côte d'Ivoire, and Togo [3]. Yams are high in phenolic compounds, protein, carbohydrates, starch, amino acids, vitamin C, thiamin, riboflavin, niacin, beta-carotene, and minerals [potassium (K), iron (Fe), zinc (Zn), calcium (Ca), phosphorus (P), and magnesium (Mg)] [4–7]. Despite this, yam tubers quickly degrade after harvest since they contain about 70% water [8]. To reduce water activity (aW) as much as possible, freshly harvested yams may be processed into dry products such as chips to minimize losses. The tubers are typically sliced into small pieces and dried in the open air or an air dryer. Drying has been found to stabilize a food product, lower aW, reduce moisture content, and prevent quality losses [9]. Foods with a moisture content of not more than 25% are described as dry or low-moisture foods. These foods are less likely to develop bacterial, yeast, mold, or enzyme damage [10]. The quality of dried foods may be impacted by pretreatment conditions and drying temperature during processing [11, 12]. Pretreatments such as citric acid, ascorbic acid, sodium chloride, edible coatings, and enzymatic treatments are commonly used in the food industry to minimize the impact of unfavorable physicochemical changes in foods that are connected to drying techniques [13].

Studies conducted by Amedor et al. [1] showed that the use of blanching and chemical pretreatments (citric acid and ascorbic acid solution) had an impact on the rate of drying and drying constant values of yam (Dioscorea rotundata) chips. Research by Kim et al. [14] indicates that pretreatment with the use of citric acid and ascorbic acid was successful in reducing the rate of enzymatic browning in apples and enhancing the color quality of potato slices [15]. The quality and physicochemical properties of dried food products are influenced by the drying process as well as the drying variables, thus influencing the consumers’ opinion [16]. Also, the quality attributes of dried food products can be described in terms of nutritional composition, level of microbial infestation, and consumer acceptability scores, based on color, texture, aroma, taste, and appearance [17, 18]. Conversely, throughout the drying process, structural and physical changes are caused by heat and moisture mass transfer [19]. To enhance the drying process and improve the quality attributes of yam products, pretreatments such as blanching and dipping in sugar, citric acid, and ascorbic acid solutions have become essential before drying food ingredients [20, 21]. According to statistics, yams postharvest losses in Ghana total 17.4% [22]. Furthermore, yam is considered an orphan crop [23]. Therefore, processing yams into dried yams (yam chips) could meet consumers’ demand for ready-to-eat food products, thereby increasing yam consumption to mitigate the highly underutilized status. Transforming yams into chips is a judicious approach to keep freshly harvested yams as a valuable product for shelf-life extension [1]. Hence, to combat the perishability of the yams, improve their nutritional value, and add economic value, we hypothesized that perishable yams must be processed into intermediate products like chips. As a result, it was necessary to process yams into high-value products, such as dehydrated yam chips, by the application of pretreatment and drying for prolonged shelf-life [24]. With a foreknowledge that the qualities of yam chips are commonly described by their color, texture (hardness or crispiness), flavor, aroma, chemical makeup, and level of enzymatic browning [25]. Understanding the chemical composition and performing sensory analysis are important outcomes relative to information about the yam nutritional profile; feedback regarding quality control, novel product development, and optimization of the production process was of research interest. Coupled with the knowledge that there is, however, a dearth of information regarding the impact of pretreatment and drying on the chemical and sensory attributes of yam chips. Therefore, the objective of this study was to determine how blanching and acid pretreatments affected yam chips’ chemical makeup, color, and consumers’ sensory appeal.

The entire study was conducted in a pilot laboratory of the University of Energy and Natural Resources (Sunyani, Ghana) and the Council for Scientific and Industrial Research (CSIR)-Oil Palm Research Institute (OPRI) in Kade, Ghana. The D. rotundata (Pona yam) variety was obtained from the open market in the Kumasi Central Market, Ashanti Region of Ghana, located at 1°37'9'' W longitude and 6°41'52'' N latitudes. Chemicals and reagents, including citric acid, boric acid, and sodium hydroxide (NaOH), were procured from the MercK Group (Darmstadt, Germany). Ether and ammonia (NH3) were obtained from Sigma-Aldrich Chem. Co., Ltd. (St. Louis, MO, USA). Hydrochloric acid (HCl), ascorbic acid, and sulfuric acid (H2SO4) were bought from VWR International (Leuven, Belgium), and all other chemicals and reagents supplied by the pilot plant and employed in the study were of analytical standard.

The flow diagram (Figure 1) illustrates the technical route of the study. The experiment was conducted in two phases. The first phase comprised the proximate composition and mineral evaluation of pre-treated dehydrated yam slices. The second phase evaluated the color and sensory quality of the pre-treated dehydrated yam slices under fried cooking conditions (chips: final product). Yam tubers were selected based on the lack of physical defects, washed, and cleansed with double-distilled water to get rid of any foreign materials. Subsequently, the yam was manually peeled and sliced into sizes of 1 cm × 1 cm × 8 cm employing a stainless-steel kitchen knife. The middle portion of the yam tubers was used for drying.

Blanching was done by dipping 300 grams (g) of yam slices in 500 mL of boiling water (100°C) for 4 min. The blanched yam slices were drained and blotted with tissue paper before drying in the oven. Untreated or unblanched yam slices served as control samples.

Yam slices (300 g) were submerged separately in 500 mL of citric acid (5% w/v, weight by volume) and ascorbic acid (1% w/v) for 30 min. Following acid pretreatment, yam samples were blotted with tissue paper before oven drying.

A convective oven dryer (Model SLN 75 POL-EKO-APPARATURA, Slaski, Poland) was used for drying the pre-treated yam slices. Before loading the samples, the oven system was left to rest (30 min) to establish a stable drying environment. The pre-treated yam samples were evenly spread on oven trays in a single layer, and the initial weight was determined. The samples were dried at 80°C and an air velocity of 2.0 m/s. The samples were taken out of the oven every hour, allowed to cool to ambient temperature, and then weighed using a digital balance (Model PL2002, Mettler Toledo, Switzerland) to determine the drying characteristics. Three replicates of each measurement were determined. Drying continued until a constant weight was observed.

The dehydrated yam chips’ moisture content was estimated according to the authorized process of the Association of Analytical Chemistry (A.O.A.C. No. 945.38). Each sample was precisely weighed at 2 g using a chemical balance (Model UB-302 IFS, England). The tray was cleaned and dried. To maintain weight, the tray and its contents were subjected to a drying oven (Gallenkamp, Model OV 880, London, England) set to 80°C for 14–15 h. The mass of the sample was then estimated after cooling in a desiccator. Until a steady weight was reached, the procedure was repeated. Using the method described in A.O.A.C. No. 945.38 [26], the percentage of moisture content was determined from the weight loss expressed as a percentage.

2 g of oven-dried samples after milling were determined in dried and pre-weighed porcelain crucibles using a balance (Model UB-302 IFS, England). Each sample was burned on a hot plate until the water and other volatile elements were removed as black fumes. In a muffle oven (Gallenkamp, OV 880 Model, London, England) that had been preheated for 6 h, the samples were then incinerated. The ash-containing crucibles were weighed and allowed to cool in a desiccator, and the percentage of ash was calculated by employing the method A.O.A.C. No. 936.07 [26].

Each specimen was weighed directly into the solvent extraction thimble and then placed within a 2 g extraction tube after being sealed with glass wool. Weighing was done before filling a 250 mL Soxhlet flask with 200 mL of petroleum ether [boiling point (BP): 40°–60°C] and refluxing it for 3 h. After the sample was cut off, the container was opened and emptied. Reconnecting the apparatus made the distillation to continue while ether was retrieved using a syphon. The flask was refluxed, moved to a steam bath to evaporate the remaining few milliliters of ether, and then left to dry overnight at 60°C in an oven. After the flask had dried in a desiccator, it was measured. The acquired crude fat was expressed as a percentage of the sample weight according to method A.O.A.C. No. 2003.05 [26].

A 750 mL Erlenmeyer flask comprising the extracted sample (from the crude fat measurement), and 0.5 g of asbestos was added. 200 mL of boiling 1.25% H2SO4 was added, and the bottle was instantly placed in a boiling dish with a condenser connected. The sample was brought to a boil for 1 min and then allowed to digest for 30 min. After 30 min, the bottle was removed and the liquid within was sieved through a funnel using a linen towel until the washings were no longer acidic. The sample was washed with 200 mL of boiling 1.25% NaOH solution before being placed back into the flask. Reconnecting the condenser to the flask allowed the mixture to boil for 30 min. It was then thoroughly cleaned with heated water until the boiling no longer tasted alkaline, after which it was filtered through a linen towel. The remaining substance was transported to a brand-new pot using a spatula, and the leftover particles were removed by adding 15 mL of ethanol to the crucible. The pot was then desiccated in a kiln (Gallenkamp, Model OV 880, England), baked for another day, allowed to cool in a desiccator, and weighed. The container and its elements were fired in a boiler (Muffle furnace size 2, England) for 30 min at 600°C, cooled, and reweighed. The crude amount of fiber was calculated as a proportion of the original weight of the trial using the A.O.A.C. 920.86 method [26].

Using a balance (Model UB-302 IFS, England), 2 g of material were weighed in a digestion flask, and then 0.5 g of selenium reagent was added. After adding 25 mL of concentrated H2SO4, the flask was shaken to achieve a homogeneous mixture. The bottle was then heated on a digestive burner for 8 h, at which point the solution became green and transparent. After that, the sample solution was transported to a 100 mL volumetric bottle, and the required volume of purified water was added. A 250 mL conical flask was filled with 25 mL of 2% boric acid, 2 drops of the mixed biomarker solution (20 mL of bromocresol green and 4 mL of methyl red), and 15 mL of 40% NaOH solution. A Kjedahl bottle was then filled with 10 mL of the digested sample solution. The condenser tip of the purification gadget was then plunged into the boric acid of the conical flask. Subsequently, the NH3 in the sample mixture evaporated into boric acid until it entirely turned bluish green. After that, the distillate was titrated with 0.1 M HCl until it was colorless. Appendix A (A.O.A.C. No. 2001.11) [26] was used to calculate the percentage of total nitrogen and crude protein. The protein content was evaluated by multiplying the nitrogen percentage by a 6.25 conversion factor.

A different approach was used to obtain the total proportion of carbohydrates. According to A.O.A.C. No. 986.25 [26], the accessible carbohydrate content was estimated by subtracting 100 from A, where A equals moisture plus crude fat plus ash plus crude fiber plus crude protein.

Mineral analysis was carried out utilizing Benton and Vernon’s approach [27]. A porcelain crucible was filled with the weighted flour sample. The blank was a crucible that was empty. The crucibles were heated to 600°C over the course of 2 h in a muffle furnace and then cooled in a desiccator. The incinerated samples were placed in a 50 mL centrifuge tube, and the containers were cleaned with 5 mL of purified water and 5 mL of aqua regia [nitric acid (HNO3); HNO3:HCl = 1:3] three times (a 2 L volumetric flask containing 1,200 mL of purified water was used as the rinse solution). The volume was gradually increased to 2 L by gently adding 400 mL of strong HCl and 133 mL of 70% HNO3, for a final volume of 2 L. To completely mix the contents, the tubes were stoppered, vortexed, and centrifuged at 3,000 rpm for 10 min. In tiny vials, the supernatant was decanted. The contents of Ca, Fe, sodium (Na), and P were measured using a flame atomic absorption spectrophotometer.

The color of the yam slices was measured using a Minolta portable Chroma meter (Minolta Co. Ltd., Model CR 310, Japan) with illuminant (D65), viewing angle (0°), and viewing area diameter (0.12 mm). Samples were left to reach ambient temperature after being taken out of the oven. Before color measurement, the colorimeter was calibrated by employing a white tile as the standard. Three observations were made for each sample to ensure measurement accuracy. The chromaticity mean values were computed by measuring lightness (L*), redness (a*), and yellowness (b*), whereas the formulae below were employed to determine the total color difference (ΔE): Browning index (BI) = [100 (x − 0.31)]/0.17, where x = (𝑎∗ + 1.75𝐿∗)/(5.645𝐿∗ + 𝑎∗ − 3.012𝑏∗).

For the fried yam slices, vegetable cooking oil (Frytol) was poured into a deep-fat fryer basket (Bush Domestic, Model FCO300, UK) and pre-heated (190°–200°C) on a hot plate (Model SC011-A, Hangzhou Joyoung Household Appliances Co. Ltd., Hangzhou, China). A sample-to-oil ratio of 1:10 (w/v) was maintained to ensure adequate heat transfer and prevent oil temperature fluctuations during frying. The yam slices secured after the pretreatment process were treated with sodium chloride and were fried for 7–10 min at 170°C with intermittent flipping to achieve a well-cooked sample. The frying temperature of 170°C ensures that moisture evaporates rapidly from the surface of the yam, resulting in a characteristic crispy texture and facilitating effective browning. This temperature also prevents excessive oil absorption, which tends to occur at lower frying temperatures [28]. The vegetable cooking oil was replaced after frying each pre-treated sample, and it was also checked and replenished after each frying test. No spices, food additives, or salt were added throughout the cooking process. After cooking, the fried yam slices were cooled at room temperature and were packaged in high-density polyethylene film (Surong Plastic Products Co., Ltd., Suzhou, China) for analysis after being lightly cleaned with tissue to remove surface oil. The experiment was done in three batches in each group. The sensory panelists were presented with the fried samples for sensory evaluation thereafter.

The fried yam slices were assessed for their sensory attributes and general acceptability using a randomized evaluation procedure. A blind randomization process was employed, where samples were assigned random three-digit codes with no treatment identification, and the order of presentation was randomized for each panelist to eliminate bias and order effects. Before the evaluation process, panelists were instructed to evaluate the sensory properties according to a scoring test questionnaire to determine which of the samples was most accepted. A 20-person non-trained tasting panel (graduate students from the pilot laboratory) was asked to rate the fried yam slices. The panel consisted of 12 women and 8 men with an age range of 34–42 years. Each panelist was asked to access each coded sample using a nine-point hedonic scale that required assessors to select their preferred likening of a product by ticking the term from a list of nine scoring terms or criteria’s (1: disliked extremely; 2: disliked very much; 3: disliked moderately; 4: disliked slightly; 5: neither liked nor disliked; 6: liked slightly; 7: liked moderately; 8: liked very much; and 9: liked extremely) that best suited their preference towards the product in terms of liking as outlined by [29, 30]. Therefore, a questionnaire was issued for the panelists to judge the sensory characteristics such as taste, color, appearance, aroma, crispiness, degree of oiliness, and overall liking. Water was served as a neutralizer before the panelists proceeded to the next sample evaluation.

The data from the analyses were analyzed using Origin-Pro 9.2 (Origin Lab Corporation, Northampton, MA, USA). Three replications were carried out, and average values were used for calculation. ANOVA and Tukey’s multiple comparison tests were used to identify significant differences between the means at a significant level (p < 0.05), and the data values were expressed as mean ± standard deviation (SD).

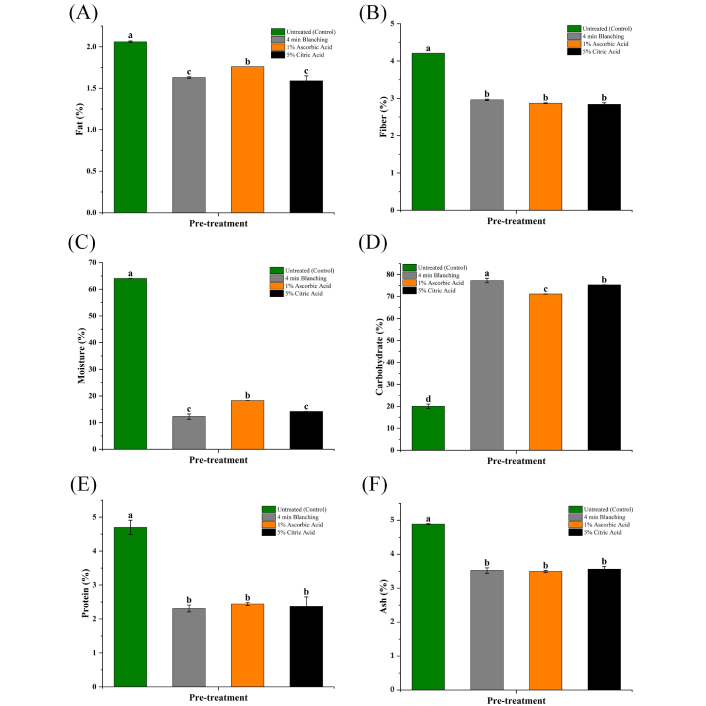

The proximate components of the dried yam chips after drying are indicated in Figure 2. The results revealed that the levels of moisture, fat, fiber, ash, protein, and carbohydrates were significantly (p < 0.05) affected by the pretreatment and drying process. The moisture percentage of dehydrated yam chips ranged from 12% with the lowest to 18% with the highest values among the treated samples, produced by 4 min blanching and 1% ascorbic acid samples, respectively. Conversely, the moisture content of the untreated yam chips was 64%. In all samples, there were significant differences (p < 0.05) between the fat percentage of the pre-treated dried samples, which ranged from 1.6% to 1.8% compared to the control samples, which had a fat level of 2.1%. Citric acid samples had the lowest fat content (1.6%), while ascorbic acid samples had the highest (1.8%) for pre-treated dry samples. Crude fiber is vital to check how sugars are utilized by the body, which helps to regulate appetite and blood sugar thresholds. Fresh yam chips had a fiber percentage of 4.3%, but dried yam chips had fiber contents of 2.9%, 2.9%, and 2.8% for blanching, ascorbic, and citric pretreatments, respectively. Fiber components may have been partially destroyed by the drying temperature of 80°C, which reduced the overall contents of the dried pre-treated samples. Again, the fact that citric acid had the least value (2.8%) of fiber may be related to the possibility that the fiber content leached into the solution during the application of the acid pretreatment, resulting in a decrease in the content.

Effect of pre-treatment and oven drying on the proximate composition of yam chips expressed on a fresh weight basis. (A) Fat; (B) fiber; (C) moisture; (D) carbohydrate; (E) protein; (F) ash. Values are mean ± SD (n = 3). a, b, c, and d mean values followed by different superscript letters are significantly different (p < 0.05); mean values followed by repeated superscript letters are not significantly different (p > 0.05). SD: standard deviation

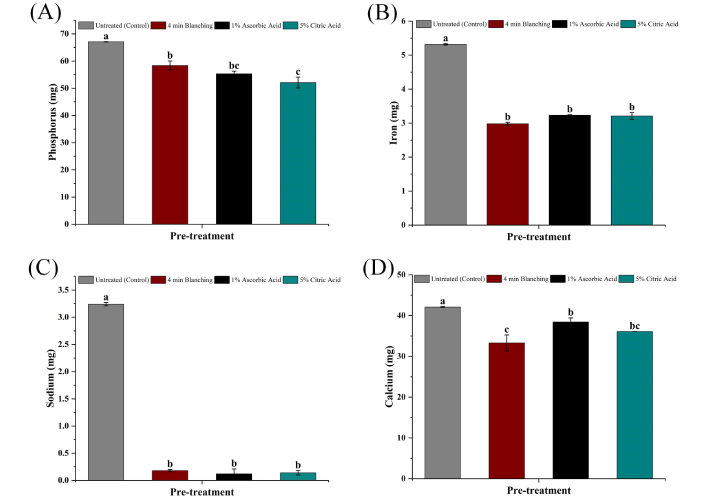

To determine the degree of mineral retention in the yam chips, the mineral content of the fresh and pre-treated yam chips was analyzed (Figure 3). The findings demonstrate that the pretreatment and drying methods used had a significant difference (p < 0.05) in P, Ca, Fe, and Na. Treatment with citric acid recorded the lowest amount of P (52 mg/100 g), while the control (untreated) recorded the highest amount of P (67 mg/100 g). In addition, the control treatment had much more Ca than any of the other treatments. Fe was also measured, with the control recording the highest level and the blanching treatment recording the lowest. The control yam chips generated the maximum amount of Na (3.25 mg/100 g), while the yam that had been pre-treated with ascorbic acid generated the lowest Na value of 0.12 mg. The untreated sample was found to have significantly (p < 0.05) more P than any of the pre-treated dried samples. All pre-treated dry samples showed a considerable reduction in P concentration.

Effect of pre-treatment and oven drying on the mineral composition of yam chips. (A) Phosphorous (P); (B) iron (Fe); (C) sodium (Na); and (D) calcium (Ca). Values are mean ± SD (n = 3). a, b, and c mean values followed by different superscript letters are significantly different (p < 0.05); mean values followed by repeated superscript letters are not significantly different (p > 0.05). Mean concentrations (mg/g) of samples of different minerals. SD: standard deviation; g: grams

A significant portion of Fe is found in hemoglobin, a type of protein found in red blood cells that transports oxygen from the lungs to all areas of the body. According to the findings, the pre-treated dried yam samples had Fe concentrations of 2.98 mg/100 g (4 min blanching), 3.23 mg/100 g (ascorbic acid), and 3.12 mg/100 g (citric acid), respectively. The untreated yam had a Fe content of 5.32 mg/100 g.

The color and the browning attributes of the fried yam chips are presented in Table 1. The L*, a*, and browning indices for the various pretreatments differed statistically (p < 0.05) from each other. The L* values of untreated (control), 4 min blanching, 1% ascorbic, and 5% citric acid-fried yam samples were 49.90, 59.00, 56.00, and 57.40, respectively. The chips’ a* values were 4.50, 3.20, 3.47, and 3.90 corresponding to untreated (control), 4 min blanching, 1% ascorbic acid, and 5% citric acid. The b* values for the untreated, blanched for 4 min, 1% ascorbic acid, and 5% citric acid-pretreatments of the fried chips were 19.08, 21.73, 21.28, and 18.40, respectively. The values of the browning index (BI) of fried yam chips for untreated, 4 min blanching, 1% ascorbic acid and 5% citric acid pretreatments were 53.52, 47.00, 42.85, and 42.88, respectively.

Color and BI of fried yam chips

| Pre-treatment | L* | a* | b* | BI |

|---|---|---|---|---|

| Untreated (control) | 49.90 ± 0.01c | 4.50 ± 0.20a | 19.08 ± 0.08ab | 53.52 ± 0.02a |

| 4 min blanching | 59.00 ± 2.00a | 3.20 ± 0.98bc | 21.73 ± 0.95a | 47.00 ± 2.00b |

| 1% ascorbic acid | 56.00 ± 0.10b | 3.47 ± 1.21b | 21.28 ± 0.36a | 42.85 ± 0.02c |

| 5% citric acid | 57.40 ± 0.20ab | 3.90 ± 1.00ab | 18.40 ± 0.20b | 42.88 ± 0.06c |

Values are mean ± SD (n = 3). a, b, and c mean values followed by different superscript letters are significantly different (p < 0.05); mean values followed by repeated superscript letters are not significantly different (p > 0.05). L*: lightness; a*: redness; b*: yellowness; BI: browning index; SD: standard deviation

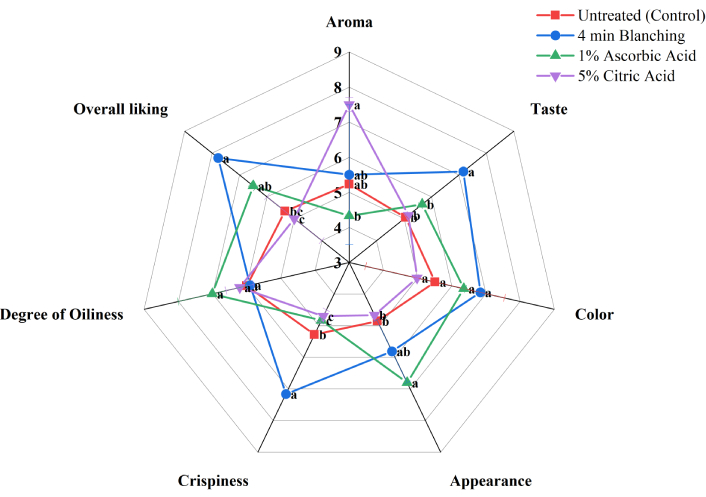

The sensory qualities of the fried yam chips, including aroma, crispiness, taste, color, and general acceptance, etc., as preferred by consumers, are presented in Figure 4. Yam chips that had been pre-treated by blanching were rated maximum in relation to taste, color, crispiness, degree of oiliness, and general acceptability, with scores of 7.16, 6.83, 7.16, 5.90, and 7.78, respectively. On the other hand, citric acid treated samples received the highest ratings for aroma (7.50), while ascorbic acid treated samples indicated higher scores for degree of oiliness and appearance. The oiliness and crispiness rating of the fried yam chips may have been significantly influenced by pre-drying at 80°C and frying at 170°C. Due to the faster rate of heat transmission from the hot oil to the yam chips at the higher frying temperature, the two-way diffusion rate increased.

Sensory evaluation of fried yam chips. Values are mean ± SD (n = 3). a, b, and c mean values followed by different superscript letters are significantly different (p < 0.05); mean values followed by repeated superscript letters are not significantly different (p > 0.05). SD: standard deviation

According to earlier observations by other scholars, the moisture content of raw D. rotundata ranged from 50% to 80% [31]. The pretreatments may have caused the yam chips to become dehydrated (by absorbing water) before drying, which could clarify the reduced moisture content of the samples of pre-treated fried chips. This is consistent with previous findings [32] that indicate that pretreatments improved moisture transmission to the exterior part. The low moisture levels in pre-treated dried yam chips may be due to the widespread gelatinization of starch, notably in the blanched products [33, 34]. Furthermore, drying at 80°C may have influenced the gelatinization process in the yam chips. The pre-treated samples for blanching, ascorbic acid, and citric acid had a corresponding moisture value of 12%, 18%, and 14%, respectively. The untreated yam samples had a moisture content of 64%. The differences in the initial moisture level of the pre-treated chips that dissipated during drying may be the cause of the disparities in the final moisture content of the dried chips. According to the findings, the moisture content of all pre-treated yam chips was less than 20%. Due to the restricted availability of water for microbial growth, food samples containing lower moisture levels have a longer shelf life [35]. The reason why citric acid encountered the least amount of fat before drying could be that certain nutrients dissolved in the solution and were later eliminated [36]. It is also possible that oxidative lipid breakdown, often known as rancidity, resulted from lipid oxidation [37]. However, the value (2.1%) for untreated yam chips was higher than the value of 0.6% for D. rotundata reported in a study by [31]. Higher drying temperatures may cause cell dehydration and cellular adhesion to break down in food products [34]. The ash content indicates inert matter and the total mineral composition of the yam chips, indicating that the control sample had a larger organic element than the samples that had been subjected to treatment. According to the findings, the pre-treated samples had ash contents of 3.5% (after blanching), 3.5% (after application of ascorbic acid) and 3.6% (after application of citric acid), while fresh yam chips had an ash concentration of 4.9%. The significantly lower ash content of the pretreated chips may be due to the high temperature of the thermal process, which may have caused some nutrients to be lost. The loss of temperature-sensitive minerals during drying at high temperatures may be the reason for the reduced values of ash [38]. Ascorbic acid yam samples with the lowest concentrations of ash can be related to the leaching of soluble minerals during the application of ascorbic acid. According to Marshall [39], the amount of ash in foods is an indicator of their overall mineral content. In this study, a protein value of 4.7% was observed for fresh yam chips. The results revealed that the protein element of the pre-treated dry yam chips decreased; the reduced contents are as follows: 2.3% for blanching, 2.4% for ascorbic acid, and 2.4% for citric acid. Due to an increased drying temperature and the emergence of complex interactions between protein and lipid, the low protein levels for the pre-treated dried yam chips may be explained by the process of protein denaturation exhibited in the yam chips during the thermal process [40, 41]. The pre-treated samples of blanched yam chips with the lowest protein value (2.3%) may be due to the soluble proteins of the samples leaking into the blanching water [42], whereas the acid pretreatment possibly affected the protein properties such as molecular weight, type, and conformation. Carbohydrates give glucose to the body, which is then transformed into energy required by cells such as those in the brain, muscles, and blood [43]. The untreated chips had a carbohydrate content of 20%, while dried yam chips that had been pre-treated by blanching, citric, and ascorbic acid applications had significantly higher carbohydrate contents at 77%, 71%, and 75%, respectively. The increase in the carbohydrate element of pre-treated dehydrated chips may be due to the substantial moisture loss in pre-treated dry samples at the high drying temperature. However, there was a significant variation in the amount of carbohydrates in each sample (p < 0.05). The findings imply that dried yam chips from D. rotundata may provide customers with a decent dose of carbohydrates. For dried Pona, Polycarp et al. [44] found a value of 158 mg/100 g, which is higher than the results found in this work. The lower mineral values of the dry pre-treated samples may be attributed to the reducing effects of the pretreatment of yam chips with citric acid, ascorbic acid, and blanching. In that, some of the minerals may have been damaged or leached because of the use of higher temperatures in thermal treatment [42, 45]. Ikwebe et al. [46] claim that one of the processing methods that decreased the mineral content of the yam samples was drying. Ca is a crucial mineral that supports strong bones and teeth. Furthermore, the mineral aids in blood coagulation and muscle contraction (FAO/WHO, 2002). The Ca element for the untreated yam samples was 42.7 mg/100 g, while the values for the pre-treated dried samples were 33.3, 38.4, and 36.1 for 4 min of blanching, 1% ascorbic acid, and 5% citric acid, respectively. Pre-treated samples had lower Ca concentrations compared to fresh samples statistically (p < 0.05). The ascorbic acid could have some level of mineral retention capacity that could explain the considerably higher Ca levels in the samples. In contrast to what was discovered in this investigation, Akissoe et al. [31] showed higher Ca levels for fresh, sun- and solar-dried white yam, respectively, of 42.3, 38.50, and 39.60 mg/100 g. The dry tissue Fe content range of 2.98 mg/100 g to 3.23 mg/100 g was lower than the results of Fe in dry weight found in the tissues of aerial yam reported by Abara [47]. The study findings demonstrate that the pretreatment procedure had an impact on their Fe concentration because samples pre-treated with ascorbic acid had a higher Fe content (3.23 mg/100 g) than samples pre-treated with other preservatives. However, the Fe values found in this study reveal that Fe is naturally present in a wide variety of foods. Therefore, it is recommended that people eat yams that contain Fe to provide their bodies with Fe for growth and development. Na is a significant mineral that influences the balance of the amount and distribution of water in the body, which is crucial for maintaining blood pressure. Fresh D. rotundata yam chips had a Na level of 3.24 mg per 100 g, but pre-treated dried samples had Na contents of 0.18 mg per 100 g (4 min blanching), 0.12 mg per 100 g (ascorbic acid), and 0.14 mg per 100 g (citric acid), respectively. There were significant (p < 0.05) differences between the pre-treated and untreated yam chips. Compared to the raw yam chips, all the pre-treated yam chips exhibited low Na values. This showed that the Na content of the yam chips was affected by pretreatment and drying techniques. These findings suggest that the amount of Na measured in this investigation was below the maximum daily recommended salt intake of < 2,000 mg/day (< 5 g/day salt) for adults [48]. However, the general mineral findings corroborated with the studies on yams [49] and cassava [45]. Drying reduced the amount of moisture and led to the leakage of certain color pigments [50]. The lightness value (L*) may not be a reliable indicator of the color quality of a fried product, as it is typically anticipated that during the frying process, some brown pigments may form. The lowest BI was found among acid-pre-treated fried yam chips. According to Kita et al. [51], ascorbic and citric acids could be attributed to their role as reducing agents, antioxidants, and inhibitors of the Maillard reaction, which limited the amount of browning of the chips during high-temperature treatment. The development of brown color in fried yam chips may be caused by the potential caramelization of sugar components in the food that is fried [52]. The degree of development of brown pigments can be affected by the type of cooking oil used in the frying process [53]. The color of a food product has a huge impact on marketability and consumer acceptance. Comparatively, Krokida et al. [53] and Timalsina et al. [54] reported similar findings among potato chips. By blocking the enzymes polyphenol oxidase and peroxidase, which are responsible for the browning and simultaneously inducing pectin methyl esterase, which results in a stiff texture, the crispiness of the blanched yam chips in this case was thought to improve sensory qualities such as texture and color. Again, the lowest oiliness score for the blanched samples may have suggested that the blanching process impacted the starch component from the surface of the chips, inhibiting oil absorption, coupled with the difference between the fried samples’ hydrophilic component content as found by Sun et al. [55]. Abdulla et al. [33] found similar tendencies for pre-treated potato chips, albeit on all sensory scales, samples pre-treated with citric acid fared better than those that had been blanched. According to the findings of this study, the ascorbic acid and citric acid treatments of yam chips resulted in low consumer preference. This could be attributable to chemical responses among vitamins and minerals, and these acids that adversely affected olfactory sensory features. The storage life of food products could potentially be determined by sensory evaluation [56]. However, customers found that the blanched sample was the most sought (liked moderately) across all sensory categories.

The study showed that, apart from the carbohydrate content, all proximate compositions experienced an overall reduction in content after drying among the treated samples compared to untreated samples. Browning was least severe in the ascorbic acid-pre-treated fried yam samples, where pretreatment and frying had a significant (p < 0.05) influence on color features. According to the study, 4-minute blanched fried yam chips received superior sensory ratings compared to other pre-treated fried yam samples. Hence, exploring the effects of pretreatment methods on the physical properties of yam samples is recommended.

a*: redness

A.O.A.C: Association of Analytical Chemistry

aw: water activity

b*: yellowness

BI: browning index

BP: boiling point

Ca: calcium

D. rotundata: Dioscorea rotundata

Fe: iron

g: grams

H2SO4: sulfuric acid

HCl: hydrochloric acid

K: potassium

L*: lightness

Mg: magnesium

Na: sodium

NaOH: sodium hydroxide

NH3: ammonia

P: phosphorus

SD: standard deviation

w/v: weight by volume

Zn: zinc

The authors thank the Council for Scientific and Industrial Research (CSIR)-Oil Palm Research Institute (OPRI) in Kade-Ghana for their technical assistance and provision of laboratory space and resources for the investigations.

ENA: Conceptualization, Formal analysis, Writing—original draft, Methodology, Software, Data curation. FS: Supervision, Methodology, Resources, Investigation, Writing—review & editing. PKB: Validation, Data curation, Resources, Writing—original draft, Visualization. EFB: Validation, Software, Writing—review & editing, Investigation, Visualization. JOK: Conceptualization, Supervision, Project administration, Writing—review & editing.

Evans Frimpong Boateng, who is a Young Editorial Board Member of Exploration of Foods and Foodomics had no involvement in the decision-making or the review process of this manuscript. The other authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

This research was approved by the postgraduate/institutional review committee of the School of Agriculture and Technology, University of Energy and Natural Resources. This study complies with the Helsinki Declaration (2024 version).

The informed consent to participate in the research sensory evaluation was secured from the participants.

Not applicable.

Data will be made available on request.

No external funding was received for this study.

© The Author(s) 2025.

Open Exploration maintains a neutral stance on jurisdictional claims in published institutional affiliations and maps. All opinions expressed in this article are the personal views of the author(s) and do not represent the stance of the editorial team or the publisher.

Copyright: © The Author(s) 2025. This is an Open Access article licensed under a Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, sharing, adaptation, distribution and reproduction in any medium or format, for any purpose, even commercially, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

Leonel Pereira

Micaela Antón ... Rafael Borneo

Rut Domínguez ... Manuel Domínguez

Eliseo Sánchez-Loredo ... Juan A. Ascacio-Valdés

Ayla Elmi Kashtiban ... Sayna Zahedinia

Shafa’atu Giwa Ibrahim, Roselina Karim

Brice Ulrich Foudjo Saha ... Lifoter Kenneth Navti

Olamide Akande ... Daniel Ajewole

Luís M.G. Castro ... Manuela Pintado

José Pinela, José Ignacio Alonso-Esteban