Editor's Picks

Open Access

Review

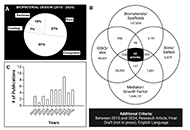

Advances in bone tissue engineering using biomaterial based scaffolds, purine crosslinking and Wnt signaling

The design of effective treatments for critical size bone defects, which result from various conditions such as trauma, infection, injury, or tumor resection, presents a significant challenge in clinical practice. While autologous grafts are commonly regarded as gold standard treatments in these complex healing scenarios, they are often associated with notable limitations, including donor site morbidity and limited graft volume. As a result, recent research trends have shifted towards developing biomaterials that better emulate the inherent complexity of the native bone structure and function through implementation of a “Diamond Concept” polytherapy strategy. Central to this approach is the utilization of biomaterials, increasingly composed of composite materials that integrate bioactive osteoinductive factors and cell sources to enhance healing outcomes. The usage of Wnt signaling specific agonists as osteoinductive mediators has been recently shown to be a promising strategy for promoting healing, as this pathway is well established to have an important role in both osteogenic differentiation and bone formation processes. Implementation of a localized delivery system through scaffold incorporation is necessary in this scenario, however, to minimize any potential off-target effects caused by the Wnt signaling cascade’s non-specificity to bone. Findings in the literature clearly show that this approach holds promise to improve clinical healing outcomes, paving the way for more effective treatment options. In this review, we will generally discuss the design of biomaterials, specifically bulk materials and composites, for the treatment of critical size bone defects. Additionally, we will highlight recent work on the design of chitosan-based scaffolds modified with purine crosslinking, to overcome cytotoxicity issues associated with other chemical crosslinkers. In this context, we focus on optimizing material design for this bone healing application and discuss the benefits of localized Wnt agonist as mediators to improve the scaffold’s osteoinductive behavior.

Open Access

Review

Advancements in hydrogel technology for ocular drug delivery

Hydrogel-based drug delivery systems (DDS) offer promising alternatives for treating ocular diseases by overcoming the limitations of traditional therapies, such as low bioavailability, frequent administration, and invasiveness. Hydrogels, with their high biocompatibility and ability to respond to external stimuli, can provide sustained and targeted drug delivery. This review highlights the unique properties of hydrogels, including their swelling behavior, porosity, and mechanical strength, making them suitable for various ocular applications. The classification of hydrogels based on cross-linking methods, origins, and stimuli responsiveness is discussed, emphasizing their potential in drug delivery for dry eye disease (DED), glaucoma, corneal alkali burns, and neovascularization. Notable advances include thermosensitive and pH-responsive hydrogels, which have shown promising results in preclinical studies. Despite these advances, most studies are still in preclinical stages, highlighting the need for rigorous human trials to validate the safety and efficacy of hydrogel DDS. Collaborative efforts among researchers, pharmacologists, and ophthalmologists are essential to translating these innovations into clinical practice, ultimately improving patient outcomes in ocular disease management.

Open Access

Commentary

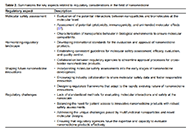

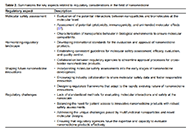

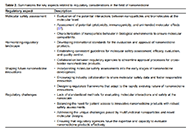

Navigating regulatory challenges in molecularly tailored nanomedicine

Nanomedicine, a convergence of nanotechnology and medical sciences, has unleashed transformative potential in healthcare. However, harnessing the benefits of nanomedicine requires a thorough understanding of its regulatory landscape. An in-depth discussion of regulatory considerations, including molecular safety assessment, harmonization of the regulatory landscape, and shaping the future of innovation, is presented in this discourse. The molecular safety assessment entails evaluating interactions between nanoparticles and biomolecules, ensuring compatibility at the molecular level. Harmonization involves developing international standards and guidelines for a consistent regulatory approach, while shaping innovations emphasizes integrating molecular safety assessments into early stages of development. Challenges encompass the need for standardized assessment methods, balancing innovation with safety, and addressing unique features of novel molecular designs. As the nanomedicine landscape evolves, effective regulatory strategies must navigate the intricate interplay of molecules and technologies, ensuring both patient access and product safety.

Articles

Latest

Most Viewed

Most Downloaded

Most Cited

Open Access

Perspective

Bioprinted enamel–dentin inlays: a future direction in regenerative dentistry

Luca Fiorillo

Published: February 11, 2026 Explor BioMat-X. 2026;3:101359

This article belongs to the special issue Innovations in Biomaterials for Dentistry and Oral Surgery

Open Access

Review

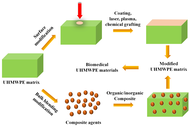

Fabrication of modified ultra-high molecular weight polyethylene via hybrid approaches for next-generation biomedical implants

Lei Li ... Yutian Duan

Published: February 06, 2026 Explor BioMat-X. 2026;3:101358

Open Access

Original Article

Amyloid fibril formation of human recombinant insulin due to the interfacial hydrophobicity of fluorocarbon polymer membranes

Kengo Mitsuya ... Satoru Goto

Published: February 03, 2026 Explor BioMat-X. 2026;3:101357

Open Access

Commentary

SABER for life saving: dynamic peptide hydrogels as a frontier in long-acting therapeutics

Deepak Chaurasiya

Published: January 25, 2026 Explor BioMat-X. 2026;3:101356

Open Access

Original Article

Osimertinib nano-niosomes: surfactant effects, release kinetics, and cytotoxicity studies

Samiah Alhabardi ... Amera Alanteet

Published: December 22, 2025 Explor BioMat-X. 2025;2:101355

Open Access

Commentary

Microneedles as a potential tool for live cell delivery in retinal diseases: a case study of Top2b-edited RPCs with matched biomaterials

Ke Yu ... Wenhao Wang

Published: December 22, 2025 Explor BioMat-X. 2025;2:101354

This article belongs to the special issue Bioinspired Material for Regenerative Medicine

Open Access

Review

Advancements in surface modification strategies of vascular grafts to improve biocompatibility and tissue integration

Noor Abu Jarad ... Tohid F. Didar

Published: September 13, 2024 Explor BioMat-X. 2024;1:241–265

Open Access

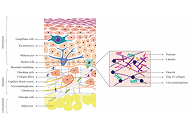

Review

Chitosan-based composite scaffolds for accelerated epidermal-dermal wound healing

Athira S. Dev ... Renu Mohan

Published: April 24, 2025 Explor BioMat-X. 2025;2:101336

This article belongs to the special issue Nature-Based Biomaterials for Biomedical Applications

Open Access

Review

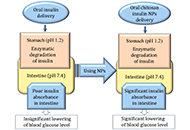

Advancements in hydrogel technology for ocular drug delivery

Doanh Truong ... Simon D. Tran

Published: December 12, 2024 Explor BioMat-X. 2024;1:331–352

This article belongs to the special issue Bioprinted Hydrogels for Engineering Tissues and Organs

Open Access

Review

Metal 3D printing of biometals for prostheses and implants: a review

Apurba Das, Pradhyut Rajkumar

Published: May 13, 2025 Explor BioMat-X. 2025;2:101338

This article belongs to the special issue Metal 3D Printing of Biometals for Prostheses and Implants

Open Access

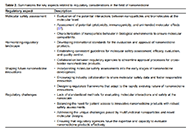

Commentary

Navigating regulatory challenges in molecularly tailored nanomedicine

Ajay Vikram Singh ... Paolo Zamboni

Published: April 25, 2024 Explor BioMat-X. 2024;1:124–134

Open Access

Original Article

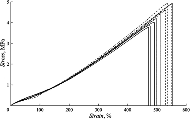

Long-term durability of silicone breast implants

Vladimir V. Shadrin ... Violetta A. Platunova

Published: April 09, 2025 Explor BioMat-X. 2025;2:101334

This article belongs to the special issue The Use of 2D Materials in Bio-tribology

Open Access

Commentary

Navigating regulatory challenges in molecularly tailored nanomedicine

Ajay Vikram Singh ... Paolo Zamboni

Published: April 25, 2024 Explor BioMat-X. 2024;1:124–134

Open Access

Review

Advancements in surface modification strategies of vascular grafts to improve biocompatibility and tissue integration

Noor Abu Jarad ... Tohid F. Didar

Published: September 13, 2024 Explor BioMat-X. 2024;1:241–265

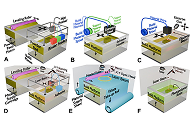

Open Access

Original Article

Fabrication and characterization of pHEMA hydrogel conduit containing GelMA-HaMA IPN for peripheral nerve regeneration

Damla Arslantunali Sahin ... Vasif Hasirci

Published: February 26, 2024 Explor BioMat-X. 2024;1:34–57

This article belongs to the special issue Nature-Based Biomaterials for Biomedical Applications

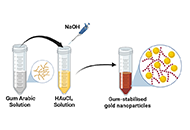

Open Access

Original Article

Gum Arabic-assisted green synthesis of gold nanoparticles as fluorescence modulator for potential analytical applications

Ahmed T. Algahiny ... Fryad Z. Henari

Published: July 28, 2024 Explor BioMat-X. 2024;1:190–201

This article belongs to the special issue Green Nanoparticles for Biomedical Applications

Open Access

Review

Chitosan-based composite scaffolds for accelerated epidermal-dermal wound healing

Athira S. Dev ... Renu Mohan

Published: April 24, 2025 Explor BioMat-X. 2025;2:101336

This article belongs to the special issue Nature-Based Biomaterials for Biomedical Applications

Open Access

Original Article

A tri-layer tissue engineering heart valve scaffold based on atelocollagen, hyaluronic acid, and elastin

Zhaoying Ma ... Jan T. Czernuszka

Published: August 29, 2024 Explor BioMat-X. 2024;1:215–230

This article belongs to the special issue Bioinspired Material for Regenerative Medicine

Open Access

Commentary

Navigating regulatory challenges in molecularly tailored nanomedicine

Ajay Vikram Singh ... Paolo Zamboni

Published: April 25, 2024 Explor BioMat-X. 2024;1:124–134

Open Access

Review

Advanced polymeric scaffolds for bone tissue regeneration

Ashkan Farazin, Seyedeh Farnaz Darghiasi

Published: June 25, 2025 Explor BioMat-X. 2025;2:101340

This article belongs to the special issue Bioinspired Material for Regenerative Medicine

Open Access

Review

Chitosan-based composite scaffolds for accelerated epidermal-dermal wound healing

Athira S. Dev ... Renu Mohan

Published: April 24, 2025 Explor BioMat-X. 2025;2:101336

This article belongs to the special issue Nature-Based Biomaterials for Biomedical Applications

Open Access

Review

Advancements in hydrogel technology for ocular drug delivery

Doanh Truong ... Simon D. Tran

Published: December 12, 2024 Explor BioMat-X. 2024;1:331–352

This article belongs to the special issue Bioprinted Hydrogels for Engineering Tissues and Organs

Open Access

Review

Nanomaterials in the treatment of degenerative intellectual and developmental disabilities

Humaira Aslam ... Misbah Ullah Khan

Published: December 13, 2024 Explor BioMat-X. 2024;1:353–365

Open Access

Original Article

A biomimetic approach to modulating the sustained release of fibroblast growth factor 2 from fibrin microthread scaffolds

Meagan E. Carnes ... George D. Pins

Published: April 23, 2024 Explor BioMat-X. 2024;1:58–83

Special Issues

Ongoing Special lssues

Completed Special lssues

Bioprinted Hydrogels for Engineering Tissues and Organs

Guest Editors: Vahid Serpooshan; Liqun Ning

Submission Deadline: June 30, 2026

Published Articles: 1

Green Nanoparticles for Biomedical Applications

Guest Editor: Priyanka Singh

Submission Deadline: June 30, 2026

Published Articles: 3

Innovations in Biomaterials for Dentistry and Oral Surgery

Guest Editor: Luca Fiorillo

Submission Deadline: June 30, 2026

Published Articles: 3

Metal 3D Printing of Biometals for Prostheses and Implants

Guest Editors: Rupinder Singh; J. Paulo Davim

Submission Deadline: June 30, 2026

Published Articles: 6

Applications of Biomaterials in Wearable Medical Devices and Bioelectronics

Guest Editor: Amirsalar Khandan

Submission Deadline: December 31, 2025

Published Articles: 0

Magnetic Materials and Their Biomedical Applications

Guest Editor: Khalid Batoo

Submission Deadline: December 31, 2025

Published Articles: 0

The Use of 2D Materials in Bio-tribology

Guest Editor: Andreas Rosenkranz

Submission Deadline: December 31, 2025

Published Articles: 1

Plasmonic Nanostructures for Designing Optical Biosensors

Guest Editor: Mohammad Tavakkoli Yaraki

Submission Deadline: April 30, 2026

Published Articles: 2

Trends in Biomaterials Research for Cardiovascular Applications

Guest Editor: Feng Chen

Submission Deadline: April 30, 2026

Published Articles: 2

Nature-Based Biomaterials for Biomedical Applications

Guest Editor: Jayachandran Venkatesan

Submission Deadline: March 31, 2026

Published Articles: 5

Bioinspired Material for Regenerative Medicine

Guest Editor: Ajay Vikram Singh

Submission Deadline: March 31, 2026

Published Articles: 6

Lignin-based Hydrogels for Energy, Sensing and Medical Applications

Guest Editor: Farzad Seidi

Submission Deadline: December 31, 2025

Published Articles: 0

Journal Information

Journal Indexing

Journal Metrics

Title: Unravelling the interplaybetween #Harmattan wind andbaroreflex functions: implicationon environmental health andcardiovascular #pathophys

Title: Unravelling the interplaybetween #Harmattan wind andbaroreflex functions: implicationon environmental health andcardiovascular #pathophys