Affiliation:

1Food Science and Technology Department, School of Chemistry, Universidad Autónoma de Coahuila, Saltillo, Coahuila 25280, México

ORCID: https://orcid.org/0000-0003-1600-405X

Affiliation:

1Food Science and Technology Department, School of Chemistry, Universidad Autónoma de Coahuila, Saltillo, Coahuila 25280, México

ORCID: https://orcid.org/0000-0002-1614-5701

Affiliation:

1Food Science and Technology Department, School of Chemistry, Universidad Autónoma de Coahuila, Saltillo, Coahuila 25280, México

ORCID: https://orcid.org/0000-0001-6304-5749

Affiliation:

2School of Agronomy, Universidad Autónoma de Nuevo León, General Escobedo, Nuevo León 66050, México

ORCID: https://orcid.org/0000-0001-8947-6125

Affiliation:

3Center for Research and Advanced Studies, Instituto Politécnico Nacional, Parque Industrial Saltillo-Ramos Arizpe, Coahuila 25900, México

ORCID: https://orcid.org/0000-0003-4284-6357

Affiliation:

1Food Science and Technology Department, School of Chemistry, Universidad Autónoma de Coahuila, Saltillo, Coahuila 25280, México

ORCID: https://orcid.org/0000-0002-6428-4925

Affiliation:

1Food Science and Technology Department, School of Chemistry, Universidad Autónoma de Coahuila, Saltillo, Coahuila 25280, México

Email: cristobal.aguilar@uadec.edu.mx

ORCID: https://orcid.org/0000-0001-5867-8672

Explor Foods Foodomics. 2025;3:101084 DOI: https://doi.org/10.37349/eff.2025.101084

Received: July 27, 2024 Accepted: January 09, 2025 Published: May 25, 2025

Academic Editor: Andrea Gomez-Zavaglia, Center for Research and Development in Food Cryotechnology (CIDCA CONICET), Argentina

Aim: Worldwide, postharvest losses of tomato (Solanum lycopersicon cv. Roma) are around 50% due to physical and biological factors being this crop, one of the most important horticultural products with extensive fresh consumption. In this work, the effects of coatings of whey protein and candelilla wax with and without polyphenols from tarbush on the extension of the shelf life and postharvest quality of tomatoes were evaluated.

Methods: An optimized suspension of protein-candelilla wax-glycerol (CC treatment) was applied as an edible coating to green mature tomatoes stored at room temperature (mature stage 2). The same suspension was supplemented with polyphenols from tarbush at 500 ppm (CP treatment). Tomato fruits without edible coating were used as a control treatment (SC). Various quality parameters were evaluated [color, weight loss, firmness, pH, titratable acidity and

Results: Tomatoes with the CC treatment showed the best shelf life extension results [color, weight loss, firmness, pH, titratable acidity, and

Conclusions: Using CC treatment, the ripening process can be significantly delayed, and the postharvest life quality of tomatoes at room temperature in the breaker stage can be extended up to this time without any spoilage.

Worldwide, tomato (Solanum lycopersicum) is one commodity with extensive fresh consumption and as an ingredient in multiple processed products. China is the main producer country of tomatoes, with a contribution of 62.8 million tons in 2021 [1]. It is a climacteric fruit that has postharvest losses fluctuating around 50% due to physical and biological factors [2], including transpiration and postharvest diseases. Tomato is a source of vitamins and minerals, as well as antioxidants, flavonoids and carotenoids that have been linked to the treatment of cardiovascular diseases and are considered anticancer agents [3].

Several technologies have been used to extend the shelf-life of tomatoes, such as: temperature control, chemical treatments, and controlled atmospheres among others. However, it is increasingly necessary to find economic alternatives that have long-term effects on fruits, that is, that comply with aspects such as prolongation of shelf life and/or keeping low production costs. Within these aspects, edible films are applied for their low production costs. Edible films generate a modified atmosphere by creating a semi-permeable barrier against gases and solutes, thus avoiding the loss of tomato properties such as: texture and firmness [4].

Reports describe these barrier films as being made up of different materials, such as polysaccharides, proteins, and waxes, among others. They can be used alone or in mixtures to take advantage of the properties of each material, one of its main benefits being its natural origin.

Proteins have proved to be attractive to generate these packaging materials, because they additionally confer nutritional value [5]. Whey protein generates films that are flexible and have good gas barrier properties when it has a previous denaturation process. Despite these excellent properties, components such as plasticizers have been added to improve flexibility, where glycerol is the most used plasticizer for its effects and low cost. Lipidic compounds such as waxes are also added to generate hydrophobicity and improve permeability to gases, surface reduction hydrophilicity, mechanical properties and barrier properties.

During emulsion formation, protein molecules are absorbed on the lipid surface, thus protecting the system from coalescing by improving its stability [6]. In addition, several natural ingredients are also added to edible films to confer antioxidant or antimicrobial activity, thus providing additional value to edible films and coatings that will be reflected in the quality preservation of fruits and vegetables.

A previous report of our research group describes the development and the optimization of edible coating made of whey protein-candelilla wax-glycerol-tarbush polyphenols, which exhibited attractive barrier properties based on the physicochemical, structural, and biological properties [7]. However, to know the real efficiency of the functionality of edible films it is necessary to evaluate its application on the target fruits. For this reason, the aim of this study was to determine the extension of tomato fruit postharvest by maintaining physicochemical properties with whey protein-candelilla wax-based edible films.

Fresh tomato fruit at the mature-green stage was obtained from a commercial supplier in Saltillo, Coahuila, México. Fruits were selected by visual uniformity in size, color (Breaking-Stage 2, Color 2) (United States Department of Agriculture, 2005), and absence of microorganisms. Before coating application, fruits were washed with a solution of sodium hypochlorite (2%) for 2 min, and air dried at room temperature.

Aqueous dispersions were prepared by dissolving protein (1.28% w/v) in distilled water at room temperature (25°C ± 2°C) for 10 min. Afterward, the solution was heated at 80°C ± 2°C for 30 min, then glycerol (0.5% v/v) and candelilla wax (0.3% w/v) were added. A homogenization at 15,000 rpm for 12 min was performed. Cooling was achieved by placing the emulsions at room temperature to bring them to less than 40°C. A vacuum pump was used to eliminate non-condensable gases from dispersions and the pH of solutions was maintained at 5.6 value. Coating treatment (CC) was selected according to preliminary experiments. An additional treatment was evaluated by adding polyphenols from a tarbush aqueous extract at a concentration of 500 ppm (CP).

Seventy fruits were immersed in each treatment (CC and CP) solution for 10 s, while control fruit (SC) were dipped in distilled water. Fruits were submerged twice once the first layer was air-dried. After the second dry layer, fruits were placed in trays and stored at room temperature (27°C ± 2°C) for 10 days. Data were recorded on the initial day (day 0) and at 2-day intervals.

During the storage period, seven parameters were monitored during tomato shelf life with sampling every 48 h. Weight loss. Weight was gravimetrically measured with an analytical balance (Explorer, OHAUS). The difference between the initial and final point was considered as total weight loss during storage calculated as percentages on a fresh basis [8]. Fruit firmness. The firmness of tomatoes was measured with a Humboldt universal penetrometer (model H-1200, Chicago, IL) by measurement penetration (mm), where samples were placed in such a way for equatorial penetration. Total soluble solids (TSS), titratable acidity, and pH. TSS was determined by method 932.12 of A.O.A.C. (AOAC, 1990) using a densimeter (DMA 35N, V2.014, Anton Paar). Changes in pH values were obtained using a pH meter (Orion model-420, Boston, MA) [9]. Changes in acidity (%) were determined by the (AOAC, 1990) 939.05 method. A sample of tomato pulp was diluted with distilled water 1:1. It was titrated with a 0.1 N NaOH titrated solution, and then 10 mL of the sample were transferred to a flask with 4 drops of phenolphthalein indicator and the sample was titrated until a pink color was obtained for 1 min. Color. The color was determined using the 3nh colorimeter model (NR110), and values were recorded as L, a, and hue angle (°Hue). Chlorophyll and lycopene content: chlorophyll and lycopene content was measured following the methodologies reported by Dere et al. [10] and Javanmardi and Kubota [11]. Appearance changes were evaluated using a photographic camera (14 Mpix Lumix, Panasonic DMC-FH6) every 2 days of storage.

Tomatoes were disinfected by submerging them for 1 min in sodium hypochlorite at 2% (v/v) and then dried completely. A cross-shaped cut of a length of 5 mm was made on each sample. Samples were inoculated with a spore solution of 1 × 106 cells/mL. Coated samples were stored at room temperature 27°C ± 2°C for 6 days. Mold growth was checked every day by measuring the diameter of material decay from the cutting site. Results were provided in millimeters.

Agilent Technologies Gas Chromatograph 7820 was used with an injection volume of 1 mL with a plastic syringe and 25 × 1 needle to both samples, a run time of 3.5 min [CO2 elutes at 1.1 min, and ethylene (C2H4) at 1.9 min]. A packed Column HayeSep Q 100/120 mesh, thermal conductivity detector (TCD) for CO2 and flame ionization detector (FID) for C2H4 were employed.

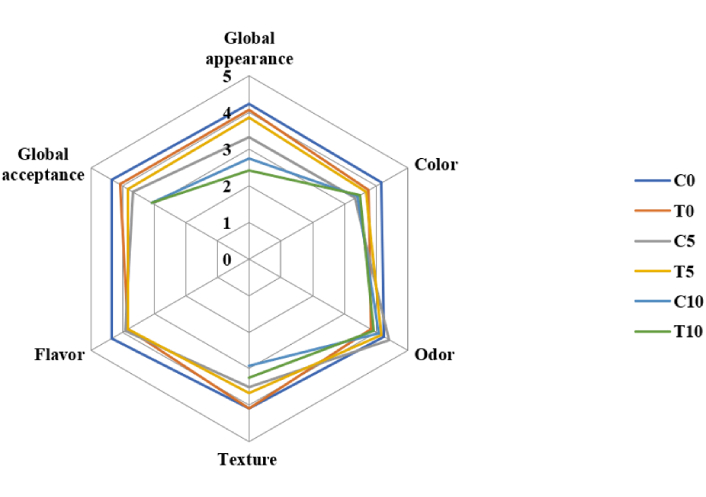

Sensory evaluation was performed only with treatments without polyphenol compounds in addition to the control. Fruit quality was estimated by evaluating attributes of global appearance, color, smell, flavor, texture, and global acceptance on the initial day, day 5, and day 10 of storage. A trained panel of 12 judges with ages ranging from 20 years to 26 years was used. Panelists were asked to score differences between samples where 1 represented extreme dislike, 2 unpleasant, 3 neither pleasant nor unpleasant, 4 pleasant, and 5 excellent for five variables (color, texture, flavor, smell, and overall acceptability).

The experiment was established under a completely randomized design (CRD) with three replications. The data were subjected to analysis of variance (ANOVA) using the computer software STATISTICA 7.0; when it was needed, the Tukey multiple comparison test was used to compare differences between treatment means at the 95% confidence level.

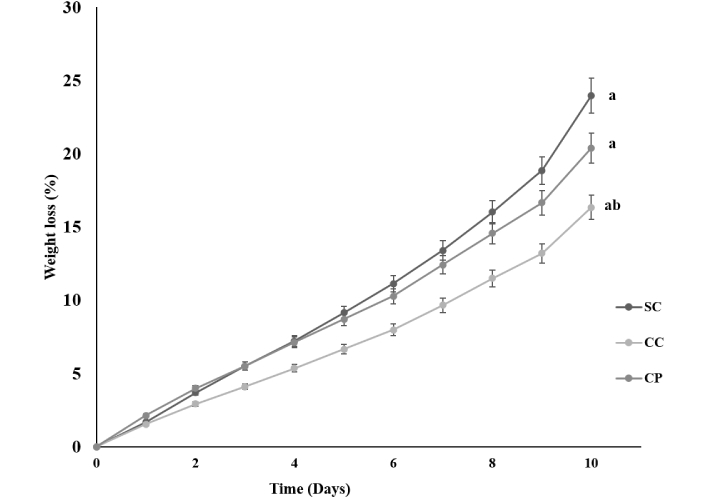

Fruit coated with CC treatment had lesser weight loss during storage than the control, in all treatments weight loss increased gradually during the storage period (Figure 1). The highest weight loss occurred between 8 days and 10 days. There is no significant difference between the CC and CP treatments, but there is a slight difference compared to the control, however, statistically there is no difference (Tukey P = 0.05).

Effect of edible coatings on weight loss during storage (23°C, 30% RH). Data shows mean ± standard deviation. Letters refer to the significant difference between treatments for each factor (Tukey test P = 0.05). RH: relative humidity

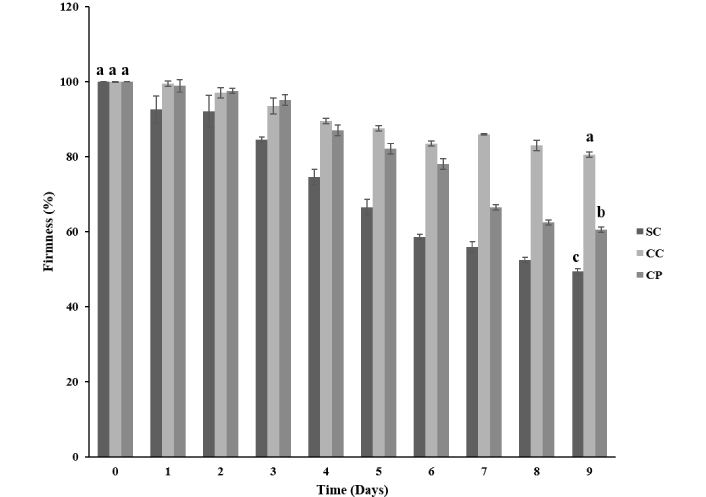

Firmness is the main attribute that is considered when selecting tomatoes by consumers, in addition to fruit color, and is of vital importance as a postharvest attribute. Firmness in fruits and vegetables is associated with cell wall composition. In the case of tomatoes, their cell walls are very susceptible, especially to physical factors such as handling. The lowest loss of firmness was obtained with the CC treatment (20%), while the control lost about 50% of the initial firmness, which was significantly different. These data were obtained at the end of the evaluation. The CP treatment showed differences with the CC treatment from day 4 of storage at room temperature (Figure 2). It can be observed in the graphs that on the initial day there were no significant differences between treatments, but at the final point, it is possible to observe that the CC treatment obtained the least loss of firmness, being significantly different from the SC and CP treatments. At the same time, the CP treatment was statistically different from the control, but the CC treatment was the best.

Effect of edible coatings on firmness during storage (23°C, 30% RH). Data shows mean ± standard deviation. Letters refer to the significant difference between treatments for each factor (Tukey test P = 0.05). RH: relative humidity

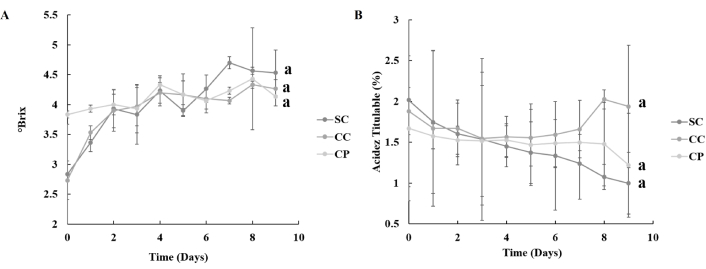

TSS usually increase during the tomato ripening process. In this study, an increase in the TSS values was observed in all treatments from day 0 to day 10 of evaluation (Figure 3A). At the end point, there is a slight change between treatments, however, the values are not significantly different. These results are directly proportional to the decrease in titrated acidity and therefore in the increase of pH values as the ripening process is carried out. Decreased titrated acidity of treated fruits and control are shown in Figure 3B.

A) Trend of values of °Brix and B) % of acidity in tomato fruits. Data shows mean standard deviation. Letters refer to the significant difference between treatments for each factor (Tukey test P = 0.05)

These values decrease during fruit storage; it was observed that the lowest obtained value was 0.99% in the SC treatment. Compared to treated fruits, these low values suggest that the coating delays fruit ripening. Values begin to decrease more noticeably from day 4 of storage. These results are directly related to pH values, which increase as titrated acidity decreases. These values are presented in Table 1 on the final day of evaluation, without significant differences between treatments.

Values of soluble solids, titrated acidity and pH

| T | °Brix | pH | Acidity (%) |

|---|---|---|---|

| SC | 4.53 ± 0.37a | 4.45 ± 0.09a | 0.99 ± 0.37a |

| CC | 4.26 ± 0.15a | 4.38 ± 0.12a | 1.93 ± 0.75b |

| CP | 4.13 ± 0.15a | 4.39 ± 0.07a | 1.21 ± 0.63a |

Data shows mean ± standard deviation. Letters refer to the significant difference between treatments for each factor (Tukey test P = 0.05). T: treatment

Color, texture and smell are the most important parameters when selecting a tomato fruit by consumers. The characteristic red color of tomato is due to the synthesis of carotenoids present in the fruit. The most consistent result with the red color was the control followed by the CP treatment and the lowest CP as shown in Table 2. Table 3 shows the content of chlorophyll and lycopene in tomatoes. Batu [12] reported that for a tomato fruit to be commercially acceptable and easy to sell it must have values that go from negative to positive for the parameter a. Negative values of this parameter indicate trends towards the deep green color while high positive values indicate trends towards deep red.

Color values L, a and °Hue

| Day | SC | CC | CP | |

|---|---|---|---|---|

| Initial day | L | 65.21 ± 0.23a | 66.17 ± 0.35a | 65.88 ± 0.65a |

| a | –2.21 ± 0.58a | –3.50 ± 0.35a | –3.53 ± 0.92a | |

| °Hue | 93.57 ± 0.56a | 96.47 ± 0.66a | 96.97 ± 0.69a | |

| Final day | L | 46.04 ± 0.55a | 62.26 ± 0.85c | 52.38 ± 1.25b |

| a | 32.15 ± 0.95b | 7.62 ± 0.61a | 28.81 ± 0.74b | |

| °Hue | 37.71 ± 0.46a | 79.28 ± 0.66b | 51.32 ± 0.91a | |

Data shows mean ± standard deviation. Letters refer to the significant difference between treatments for each factor (Tukey test P = 0.05)

Content of chlorophyll and lycopene in tomatoes

| Day | Chlorophyll (mg/g sample) | Lycopene (mg/g sample) | ||||

|---|---|---|---|---|---|---|

| SC | CC | CP | SC | CC | CP | |

| Initial day | 2.74 ± 0.54a | 3.23 ± 0.15a | 2.87 ± 0.36a | 4.84 ± 0.71a | 2.01 ± 0.35a | 3.45 ± 0.19a |

| Final day | 0.95 ± 0.97b | 2.13 ± 0.26a | 1.77 ± 0.94ab | 64.38 ± 0.52b | 9.93 ± 0.36a | 36.16 ± 0.02ab |

Data shows mean ± standard deviation. Letters refer to the significant difference between treatments for each factor (Tukey test P = 0.05)

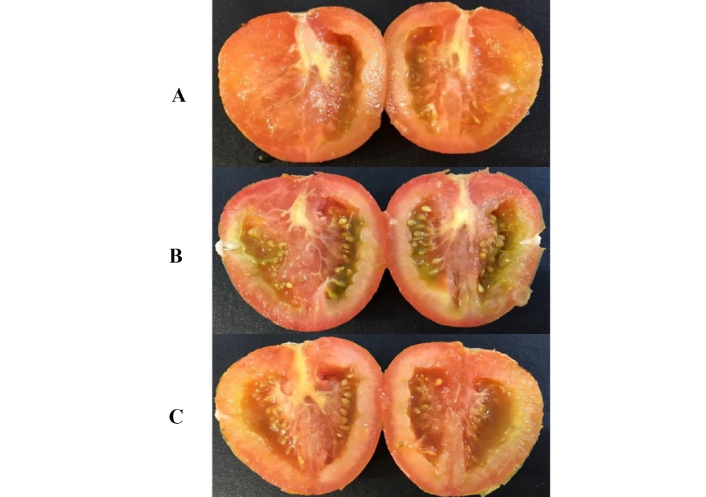

The deterioration of tomatoes is shown in Figure 4. It is observed the treatments to the initial day, where visually there are no differences between the colors. At the end of the evaluation, the CC treatment shows the coloration with a tendency to orange, while the rest is towards a deep red color, demonstrating the effect on the ripening delay when applying protein-based whey and candelilla wax coatings.

The SC treatment showed the best result against the phytopathogen Rhizopus stolonifer with a growth of 38.22 mm of radial growth, while the CC and CP treatments showed growth of 49.25 mm and 40.72 mm, respectively. By observing the fruits internally, it was realized that in the SC treatment, the microorganism managed to reach the interior, causing liquefaction of the soft tissue, as is shown in Figure 5, allegedly caused by the generation of enzymes that degraded the internal fruit walls. This was not observed in CC and CP treatments, having a positive effect when coatings were applied.

Appearance of tomato fruits inside at the end time of evaluation against Rhizopus stolonifer. A) SC; B) CC; C) CP

All samples increased their respiration rate during ripening, which can be corroborated with the data shown above, showing that metabolic activity continues even with the application of the coating. After 10 days of storage, the CC treatment showed the lowest CO2 production value (17.21 mL kg–1 h–1) compared to the control treatment (19.03 mL kg–1 h–1), indicating that coating may have modified the internal atmosphere of the fruit, decreasing the respiration rate. The same behavior is observed with C2H4 production. The lowest value found was with the CC treatment (4.66 L C2H4 kg–1 h–1), compared to the SC and CP treatment (7.07 L C2H4 kg–1 h–1 and 6.13 L C2H4 kg–1 h–1, respectively) at day 6 of evaluation.

The reduction in C2H4 production results in a delay in the ripening processes. A similar behavior was observed by Ruelas-Chacon et al. [13], where the highest CO2 value was (10.7 mL kg–1 h–1), similar to that obtained in this research, it should be noted that the coating forming material employed by these authors was Guar gum.

Sensory evaluation was performed only for SC (C) and CC (T) treatments, the CP treatment was not evaluated in this trial due to previous results where the best result was obtained with the CC treatment.

The test revealed differences between the evaluated treatments. No significant differences were found on the initial day, but as the storage time increased, significant differences were found by the panelists. The results are shown in Figure 6, where the scores given by the panelists to all the attributes were between 3 and 4, which is interpreted as “good” and “very good”, respectively. It can be observed that there is a similar preference in all treatments in the case of odor, which indicates that there are no perceivable differences in this parameter. Likewise, we can observe that as the days of storage increased, appearance and overall acceptance by the control and treated tomatoes were affected after 10 days under the test conditions. The rest of the analysis shows similar results between units with treatments and days of storage.

Evaluation of saladette tomato attributes. C: control units; T: units with coatings 0, 5, and 10 days of storage at room temperature (data shows mean value)

Sensorial results suggest that the protein coating can be used to extend the shelf-life and improve tomato quality during storage at room temperature (22°C ± 2°C). C and T saladette tomatoes were not sensory analyzed after 10 days of storage based on the microbiological results.

Ali et al. [14] mentioned that weight loss is due to the transpiration process which causes a weight reduction. Also, the response variable is caused by vapor pressure at different locations of fresh fruits and vegetables. The coating acts as a semi-permeable barrier against moisture movement and oxygen (O2) and CO2 gases, reducing respiration rates and water loss. It is also important to note that tomatoes with CC treatment maintain the slightest increase in weight loss, while in the other treatments (SC and CP), the difference in weight loss is shown from day 5 of storage. In other studies, Salas-Méndez et al. [15] observed the same behavior when biodegradable packaging is applied to tomato fruit. These authors worked with nanolaminates from chitosan and alginate, forming layers between applications. Ghaouth et al. [16] reported that wax application in formulations contributed to the reduction of weight losses of tomatoes due to their hydrophobic character.

The softening of fruit cell walls can be attributed to the enzymatic degradation of cellular structure and cell wall components. Limited levels of O2 limit the activities of these enzymes, resulting in firmness retention during storage [14].

TSS, titratable acidity and pH value changes are attributed to the presence of organic acids in tomato fruit, which are degraded as the ripening process is carried out. When low O2 levels are found due to the semi-permeable barrier in treatments, this use of organic acids is delayed, and therefore the delay of ripening is favored [17, 18].

During the ripening process, the green pigment of chlorophyll is degraded and results in the accumulation of carotenoids, mainly lycopene, giving rise to the characteristic red color [14]. These results are consistent with the amount of chlorophyll and lycopene (mg/g sample) found in samples on the start and end day of evaluation as shown in Table 3. Thanks to these color values, it is possible to determine the rate of maturity in which the treatments are located according to the USDA classification scale. It is observed that the CC treatment has the lowest value, and such behavior is completely attributed to the barrier created on fruit with the edible film [12].

This study shows that protein-based coatings and candelilla wax delay the ripening process of var. saladette tomatoes at room temperature. The ripening process can be significantly delayed, and the postharvest life quality of tomatoes at room temperature in the breaker stage can be extended up to this time without any spoilage using CC treatment.

C2H4: ethylene

CO2: carbon dioxide

O2: oxygen

TSS: total soluble solids

Authors thank the National Council of Humanities, Sciences and Technologies (CONAHCYT, Mexico) for all financial support and the scholarship awarded to Olga B. Álvarez-Pérez for her PhD studies at Universidad Autónoma de Coahuila, México.

OBÁP: Conceptualization, Investigation, Writing—original draft, Writing—review & editing. CTL: Supervision, Writing—review & editing. JMVS: Supervision, Writing—review & editing. RR: Writing—review & editing. MAAG: Supervision, Writing—review & editing. RRH: Writing—review & editing. CNA: Conceptualization, Investigation, Project administration, Writing—review & editing.

Cristóbal N. Aguilar who is the Editorial Board Member of Exploration of Foods and Foodomics had no involvement in the decision-making or the review process of this manuscript. The other authors declare that they have no conflicts of interest.

Not applicable.

Informed consent to participate in the study was obtained from all participants.

Not applicable.

The raw data supporting this manuscript’s conclusions will be made available to the authors without undue reservation to any qualified researcher.

Not applicable.

© The Author(s) 2025.

Open Exploration maintains a neutral stance on jurisdictional claims in published institutional affiliations and maps. All opinions expressed in this article are the personal views of the author(s) and do not represent the stance of the editorial team or the publisher.

Copyright: © The Author(s) 2025. This is an Open Access article licensed under a Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, sharing, adaptation, distribution and reproduction in any medium or format, for any purpose, even commercially, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.